We manufacture and fabricate customized floor drain covers in variety of sizes, loads and drainage. We also produce improved steel metal grate panels and steel metal grating weldments for vehicular and pedestrian traffics. Obviously, the vehicular traffic grating differs significantly from pedestrian traffic grating due to increased resistance to heavy loads and dynamic loads. The customization of floor drain covers involves not only obvious factors such as shape and sizes, but also dynamic and static loads and drainage. Additionally, it involves existence or lack of drain cover’s support and its size and shape.

We do not recommend other types of grating for drain covers a these other types are more suited for different purposes.

JW Investrade Inc. is a mother company of JW Portable Welding & Repairs. We have more than 20 years of combined company’s experience in designing, manufacturing & fabrication of customized floor drain covers .

We install our floor drain cover in automotive industry such as car dealerships, mechanical shops, and carwashes. They are popular in heavy truck washes, and detailing businesses. These drain covers are also in demand in variety of warehouses and floors of factories where they are exposed to heavy impact and heavy loads. The real estate industry welcomes them in condominiums and apartment buildings. We ship them also to clients in petrochemical, petroleum, pulp & paper and recycling industries.

Floor drain covers for vehicular traffic

Our floor drain covers for vehicular traffic sustain

- high loads,

- high impact & vibration,

- abuse of drivers and

- corrosion.

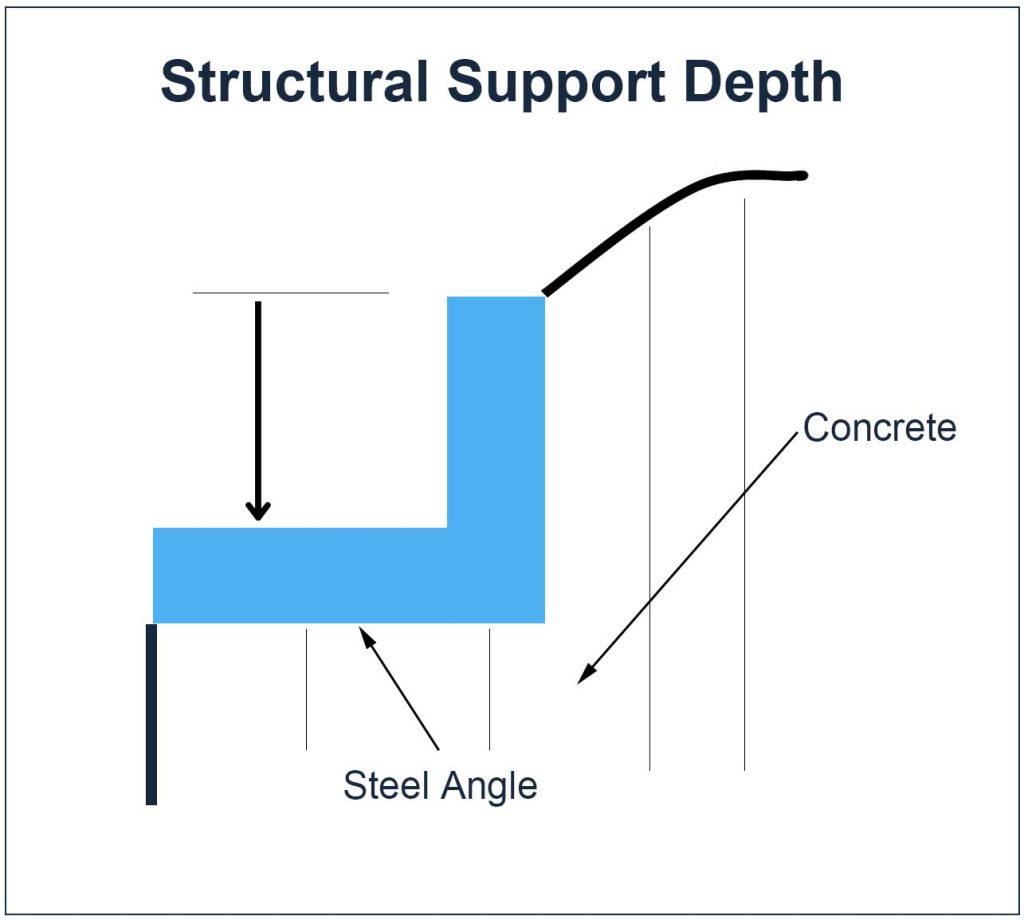

We install them on drains with typical steel angle’s support or without it. The installation without steel angle support involves placement of the cover directly on the concrete. This is a “drop in” version of our drain cover. When approaching the “drop in” version the drivers will face a 3/8″ to 1/2″ step up.

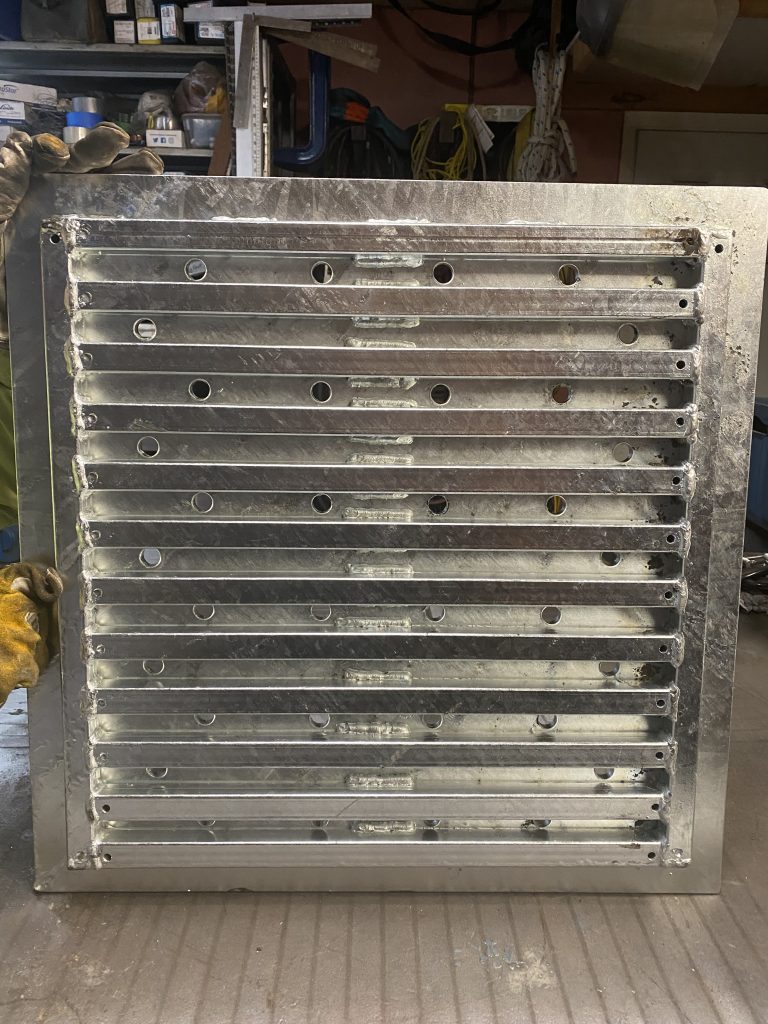

In designing of your cover for vehicular traffic, we have sacrificed high drainage to increase resistance to loads, to impact, to vibration and to twisting. Pending on the drain cover structure, we can increase drainage or reduced it as required by our client.

Major components

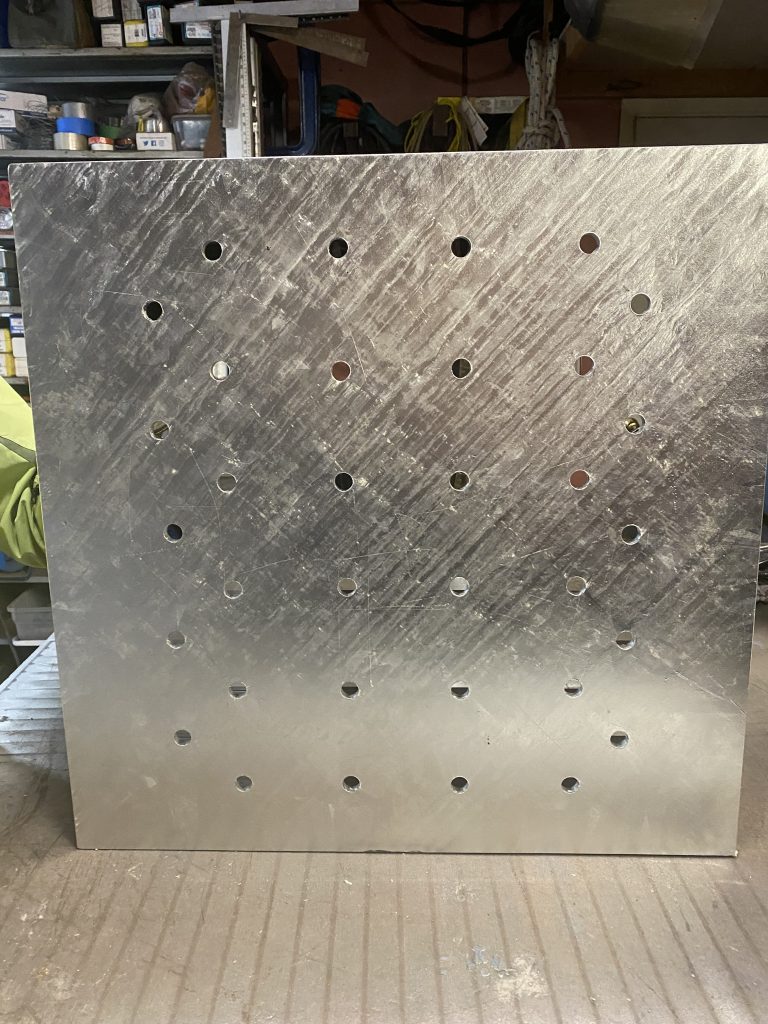

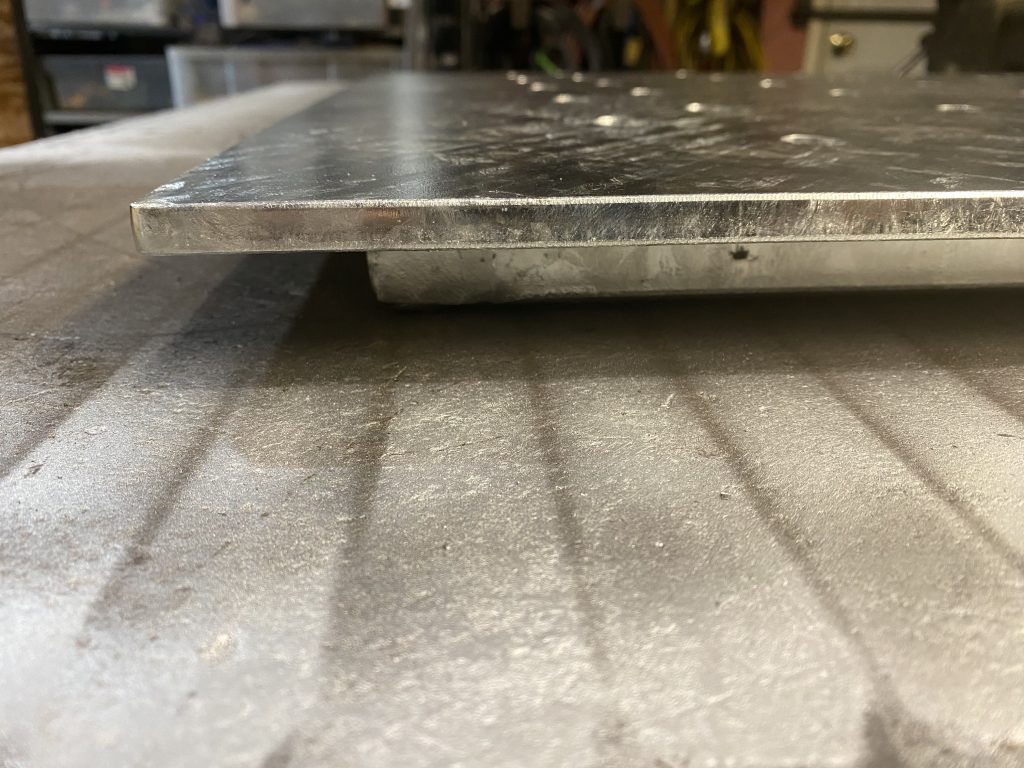

The major components of our drain cover for floors include top steel plate and supporting load structure. The top steel plate’s thickness varies from 3/8″ to 3/4″. Thickness depends on load and impact as well as minimum drainage factor. Pending client’s request we can use mild steel or Q&R steel for the plate.

The supporting load structure could consist of structural components such steel angles for light loads, channels, or hollow structural tubes. These hollow structural tubes could be square ( HSTS) or rectangular (HSTR ). The supporting load structure supports the load as the name suggest. It also prohibits the horizontal movement of the cover.

Depth of our floor drain cover

The depth of our floor drain cover depends on the depth of steel angle support and the structural elements of the support depend on the maximum load. We definitely prefer the use of HSTS’s or HSTRs for support’s bearing bars. However, the restrictions of structural support width forces us to use channels instead.

We eliminate heavy lift and pinching hazard during installation with lifters

Our drain covers for floors are heavy. They weight depends on their size and thickness of materials used. Therefore they can create heavy lifting and pinching hazards. We eliminate or reduce significantly these hazards by selling our drain covers with lifters. Our lifters not only help you lift the cover with your partner but also help you installed it properly. Our cover lifters make removal and installation of floor drain covers comfortable during maintenance and inspection of drains.

Resistance to high load, impact, vibration, & abuse

Our customized floor drain covers resist high loads, high impact, vibration and abuse. Therefore while ordering them we need to know where you are going to install them. And what kind of loads they will carry. Please specify in our contact page to where you will be installing our floor drain cover with following options available:

- Warehouse

- Mechanical shop

- Factory

- Detailing shop

- Carwash

- Yard

- Other

This simple selection will allow us to predict the frequency and size of abuse. This selection will also indicate if drivers turn wheels while vehicle stands on the cover.

Additionally, we need to know what kind of vehicles will drive on our drain covers. Therefore, you will have to chose from following selection

- Nothing

- Pedestrian traffic

- 1 Ton Forklifts

- 2 Ton Forklifts

- 5 Ton Forklifts

- Heavier than 5 Ton Forklifts

- Passenger Vehicles

- Pickup Trucks

- H-10

- H- 15

- H – 20 / HL- 92

- H – 25

- Heavier

The above selection will allow us to estimate the maximum load and maximum impact on our drain cover.

Square sizes of our floor drain cover

We not only accommodate our floor drain covers to subjected loads and impact but also to size of drains openings. Most popular shapes are squares 12″ x 12″, 18″ x 18″ and 24″ x 24″. We also accommodate sizes of fabricated floor drain cover to other sizes for clients with older drains. These older drains have openings in many untraditional sizes. Please visit grating steel measurements to become familiar with drain cover measurements and additional information we require prior quoting your project.

This is how we have started with our drain cover in 2016. We just had to respond to client who urgently needed to cover the drain.

Rectangular floor drain covers suit narrow trenches.

These narrow trenches create headache for manages. Heavily damaged old grating damages tires of vehicles and driving over collapsed drain cover could create some hazards to vehicles. Additionally, workers could trip over the damaged drain cover.

Our floor drain covers that feature 3/8″ thick steel plate provides perfect resistance to impact coming from multiple directions. This steel plate also responds very well to turning of wheels standing on the cover.

The structural support under the plate prohibits bending the plate. It also allows for transfecting the load to angle steel support structure in the concrete. Since we use hollow steel tubes as structural support, we have increased the surface of load bearing acting on angular steel support. Therefore, we have reduced significantly concentrated load acting on steel angles support. That is why our drain cover extends the useful live of the steel angle support in the concrete.

Additional benefits of our floor drain cover for narrow drains/trenches

Additional benefit of increased surface for load transfer which in our case is at least 1″ or 1 1/2″ is the possibility to place it in spots where steel angle support is rusted out. Although we do not recommend placing them directly on concrete. But in emergency, you could do it to buy yourself some time. However, we still recommend to fix the angle support while our floor drain cover will do its job.

Having flexibility in thickness of the plate and flexibility of sizes for hollow structural tubes we can adjust the depth of our drain cover. This depth adjustment will eliminate the impact of wheel going from higher elevation of concrete to lower elevation of the drain cover. Our drain cover also provides the sufficient drainage.

Old rectangular floor drain/trench covers

The rectangular shape of drains in the floor, the so called narrow trenches require special attention. They are most popular among our clients since they adjust the size of drain to the level of drainage required. They maximize the square footage of concrete while maintaining some drainage. Most of them are covered by variety of steel grating.

Most of floor drain covers made from steel grating fail rather quickly in these narrow drains/trenches. Question is why do they collapse? We have performed significant number of inspections supported by measurements of cracks and bows of these drain covers. We have concluded that positioning the bearing bars across the smallest distance in these narrow trenches does not work since this grating is not damaged by excessive load. They are damaged by excessive dynamic load and impact coming from multidirectional vehicular traffic. Certainly, positioning the bearing bars along the length of rectangular shape will make the situation even worse.

The steel grates in these narrow trenches can not simply sustain the impact of vehicles driving in multiple directions over these grates. To make things worse, many drivers turn their wheels while standing on these grates and this damages the grates even more. Driving in circular pattern damages these grates too. Moreover, the impact of wheel going from higher elevation on concrete to lower elevation on floor drain cover amplified the damages.

Floor drain cover accommodates permanent concentrated load

In many warehouses, mechanical shops and factories, space is very valuable. Sometimes the drain location does not suit your layout for leg placement of heavy shelving, toolboxes or steel work tables. Also, the drain location does not allow for wheels placement of small equipment, and carts or even forklift’s wheels.

Our floor drain cover provides a solution to your layout problem since you can permanently place concentrated loads on top of it. The 1/2″ steel plate with support of bottom structure will carry the significant concentrated load and it will not bend due to supporting structure under it.

Our floor drain cover for drains with no steel angle support

Our floor drain cover for drains with no steel angle support features top plate extending pass the cover support structure by about 1 1/2″ on each side. Therefore, the extending plate is responsible for transferring the load to the concrete. The structural support of the plate prohibits bowing of the plate under the load.

The structural support of the plate also prohibits the horizontal movement of the floor drain cover. We tend to keep the distance of about 3/8″ between concrete and steel support of the plate. We simply expect that older version of drains have very unregular walls.

Traction is minimized

The only weakness of our drain cover is deficiency of traction but this weakness is significantly minimized. First, this narrow floor drain cover is usually 6″, 8″, 10″, 12″ with some varieties between. Therefore, most of the time a wheel goes partially only on the cover. Very rarely it happens for 2 wheels and never happens for 4 wheels.

Our clients so far have never complained about reduced traction while driving on our floor drain covers.

Circular shapes

We also fabricate circular shapes for this model in variety of radiuses but they are not as popular as square and rectangular shapes. Additionally, we produce circular angle supports to accommodate circular shapes of the cover. In most cases, the steel support in the concrete disintegrates much faster for circular shapes floor covers. Our clients must replace not only the floor drain cover but also its structural support.

Floor drain covers for pedestrian traffic

The floor drain covers for pedestrian traffic include drain covers from mild steel, stainless steel and from composite materials. Both types have its advantages and disadvantages. When considering installation of floor drain covers for pedestrians such factors as cost, strength, safety, corrosion resistance should be considered. And, sometimes clients must make compromising decisions that will affect their operation for a long time.

Drain covers for pedestrian traffic for drains with steel angle support

We produce drain covers for pedestrian traffic for drains with steel angle support from steel grating suitable for sidewalks. These drain covers features usually traditional heavy steel banding bars instead of our banding tubes. The steel grating suitable for sidewalks provides good support for pedestrians and it welds well under our stringent welding procedure.

Most importantly, these drain covers have extended utilization time since the steel angle support of the drain provides sufficient load support to the cover. If done properly this type of drain cover will hold the load of one axle without any problem.

Drain covers for pedestrian traffic for drains without steel angle support

We produce also drain covers for drains without steel angle support for pedestrians. However, please note that they cannot sustain any vehicular traffic what so ever. These floor drain covers have a steel frame built from reversable steel angles. The angle horizontal toe put on top of concrete provides the load support. The vertical toe is welded to steel grate.

The 2 steel angles replaces 2 bandings and the 2 external rim bearing bars are also replaced by these angles. In this way, the cover just hangs on top of the opening and reversable angle frame provides support of the load.

Unfortunately, such structure does not support the incoming vehicular traffic very well. Even if we weld the bearing bars to the reversed angles’ rim with our welds. We usually chose the mesh type bar grating for this purpose therefore we are sometimes unable to place our antivibration welds due to lack of space between bearing bars. This type of cover creates multiple hazards to vehicular traffic due to their load and impact.

We are developing models of drain covers for pedestrians that will sustain half axle vehicular traffic.

Stainless steel drain covers for pedestrians

The stainless steel floor drain covers are popular in commercial facilities where corrosion can contaminate production process or final product. The food processing and food production facilities prefer stainless steel drain covers. Additionally, pharmaceutical, and chemical industries also prefer stainless steel drain covers. In many of these industries galvanized steel is not allowed due to zinc contamination. That is why only stainless steel products are approved.

Stainless steel floor drain covers are rather expensive. Canadian suppliers do provide limited selection of light grating for these drain covers. Some American manufacturers run occasionally production line with stainless steel grating. Therefore, clients must wait a long time for specific stainless steel grating or they must import it from other countries.

In most cases, clients decide to compromise the ideal stainless grating panels for stainless grating panels with much thinner bearing bars. Also, many clients decide to sacrifice the quality of stainless steel in order to move the project ahead. As a result these clients settle for stainless steel drain covers made from grating with very thin bearing bars. And, drain covers with lowest quality stainless steel.

The grating panels made with lower quality stainless steel tend to corrode in some harsh environment. Additionally, thinner than expected bearing bars do not resist impact sufficiently. Consequently, projects are consistently compromised by impact and corrosion. Therefore, patience and proper planning makes sense in projects involving stainless steel floor drain covers.

Proper engineering also impacts the success of the stainless steel floor drain cover. Wider surfaces for drain cover support minimize bowing of drain cover especially in presence of grating with thinner bearing bars.

Our involvement in stainless steel drain covers

We occasionally have been involved in customization of stainless steel drain covers. We have imported the stainless steel grating directly from offshore producer and then waited almost 5 months for import delivery. Finally, we have got what we wanted.

Our client’s layout did not allow for any vehicular traffic going on these stainless steel drain covers with drains located on lower level close to stainless steel boilers and no ramp. The drains opening had traditional angle supports made also from stainless steel for supporting the stainless drain covers. Our involvement was reduced to welding of stainless steel banding and precise cutting.

Since warpage risk is a well known issue when welding stainless steel, we have reduced our anti vibration welds present on each side of bearing bar to welds present just on one side of bearing bar. But, we have welded the whole depth of the each bearing bar. Due to lack of vehicular traffic in this area such approach was justifiable. In this way we have also met the industry standard welding procedures.

Composite floor drain covers for pedestrian traffic

Composite floor drain covers are becoming more popular due to their lower cost, sufficient load caring for pedestrian traffic and corrosion resistance. They are also preferable in areas where regular maintenance regiment demands frequent removal of drain covers. Additionally, they improve safety when conducting work while standing on them or kneeling on them. And, they quickly remove hazard of slipping on concrete with flowing water.

Manufactures sell composite floor drain covers in comfortable for handling panels. These panels are very easy to cut for specified location.

There are two kinds of composite drain covers, molded and pultruded. The molded drain covers are less expensive. They are also more comfortable to use since you can place it without any span consideration. However, the pultruded drain covers sustain higher loads and should be installed along shorter span. They are also more expensive and more difficult to cut.

Contact us to quote

When you land on contact us please fill out the initial info. and then chose drain cover, then select quantity, location in your facility and what drives on the cover. Then provide other details and images of drain(s)