As our logo suggest, we specialize in custom metal grating used to support vehicular traffic and in some applications to support pedestrian traffic. Our specialization focusses, however on applications where significant dynamic loads of multidirectional vehicular traffic damage existing grating. JW Investrade Inc. is a mother company of JW Portable Welding & Repairs. And after 10 years we have decided to separate some metal gratings from other welding activities. The impact, heavy dynamic loads and grating depth restrictions play the most detrimental role in degradation of grating for vehicular traffic in secondary market. And, then comes the rust as a cherry on top of the cake.

Traffic of passenger vehicles, pickup trucks, midsize trucks, semitrucks, forklifts, and other machinery shortens the life span of metal grating. The vehicles and machinery are getting bigger and heavier causing heaver static and dynamic loads. And the have much bigger concentrated impact on grates. The aging infrastructure does not allow to increase the thickness of the panels.. The increase of grating depth (thickness) which will allow for utilization of more resistant grating comes at significant cost. The budget constrain forces managers to replace the degraded metal grating with the same type of metal grating while expecting different results. The vicious circle of short life span of metal grating persist in secondary market.

Other industries for metal grating

In other industries the situation is similar, although not as extreme. In water treatment plants flowing liquids have the same damaging effects to grating as their movement cause grating’s vibration under significant loads. The friction of water caring small solid particles removes metal in similar fashion as grinding damaging bearing bars. The flowing air has the same characteristic as flowing liquids although loads and vibrations are much smaller. Therefore we apply the same principles of improvement to filtration grating as to metal grating for vehicular traffic.

More about JW Investrade Inc.

As mentioned above JW Investrade Inc. is a mother company of JW Portable Welding & Repairs with office located at 594 Cranbrook Rd., London, Ontario. However, the sophisticated cutting, assembly and complex welding is located at 5558 Clandeboye Dr. in Lucan. We have been looking for a long time into purchasing a suitable welding/fabrication shop for our metal grating operation, and finally at the end of July we have finalized the deal for the shop in Lucan.

Why welding shop in Lucan?

As everybody knows, the real estate market is highly inflated and small companies simply cannot afford a decent industrial property. In fact, rents in all our previous locations were quickly increased once the owner have noticed a significant business activity in the shop. Therefore the only option left was to buy a welding shop on industrial land. With one or two industrial properties for sale in London per year, the purchasing task was not easy.

We also wanted to increase our market share in equipment repairs of JW Portable Welding & Repairs as we have predicted a significant decline in business activity in Ontario.

Here is our shop.

With so much land to our disposal, we are already planning construction of second shop to the left of the existing one.

JW Investrade Inc. business operation

We fabricate all custom grating including custom trench covers, drain covers, ramps in the shop since it contains variety of equipment that allows us to cut and weld very precisely our weldments. The improvements of ventilation and introduction of modern lights have made this shop more comfortable for welders. The presence of large welding tables made corrections to warpage more efficient.

We ship and install all custom products from this location using variety of trailers.

Our Customers And Product Characteristics

Our customers in vehicular traffic market include factories, dealerships, heavy truck washes, mechanical shops, warehouses, water treatment plants, chemical plants, mining, pulp & paper, oil refineries and petrochemical plants, railroads, airports, agricultural facilities and many other commercial businesses. We also serve pedestrian market with metal gratings for trenches and pits without traditional metal angle support and without involvement of crane. Additionally, we serve pedestrian market with grates of finesse shapes that will closely accommodate to structures going through grating. Therefore we do not provide metal grating for catwalks, variety of mezzanines, railing infill panels, stair treads, and walkways. However, please contact JW Portable Welding & Repair if you are in need to repair them. JW Portable Welding & Repair provides also on site grating repair for vehicular traffic in local area within 150km radius from London, Ontario.

Our custom metal grating

Most often customers call us when their grating is in last stages of disintegration with holes, extreme bowing and rusted.

Unfortunately, most of this disintegration is highly premature and the utilization period has been cut by 40% to 70% or even more. By analyzing the parameters of grating that include dimensions of metal bars, gaps or openings, load capacity and suitable maximum span, location, surface, condition of support, and the environment, we develop a reasoning for the grating’s premature failure. And then we propose the type of grating that will suite the client’s better. Such proposal usually involves custom improved grating of the same type as your old one, or of heavier grating, or custom grating weldments. We also produce heavy built drain covers, compound grating panel in different shape and sizes that supports extreme dynamic loads. We ship the grating panels Canada wide and we are ready to ship to US.

New improved metal grating

We work with all popular metals including steel, stainless steel and aluminum. And, some of our custom grates for screens involve more advanced alloys. Aside of fabrication of improved grating, and custom grating weldments, we also fabricate drain covers for drains and trenches by welding harden and quenched plates with traditional grating, or with custom structures. Our improved grating, grating weldments, and drain covers seem to resist better stressful and rigorous conditions. We hot deep galvanize majority of our steel grates.

So far, majority of shipments of our improved grating is destined for Ontario but we have shipped some new metal grating to clients to other provinces last year too. Stainless grates and aluminum grates form rather peripheral market for us due to high stainless steel cost, lower than expected quality of material coming from Asia and low resistance to vibration of aluminum grates. Stainless steel and aluminum grating belong rather to group of gratings supporting pedestrian traffic in special applications.

All our grating panels are removable for scheduled maintenance, trench cleanup, and occasional rotation. Some applications require saddle clips, “G” clips or “J” clips. However, most applications involve weld lugs due to weld lug antivibration characteristics. Over the last few years we have reduced utilization of countersunk bolts due to their limited resistance to vibration.

Old grating

We attempt to repair old steel grating in place if it is not rusted too much. And, if the bowing does not exceed our standards. Through JW Portable Welding & Repair, we offer steel grating repair service locally in Southern Ontario. You can find more about repairs of old grating here

In regards to steel grating repair, we are able to repair a panel with up to 3 in the row twisted bearing bars. However, we recommend to replace panels with more than 3 bearing bars twisted in the row. We recommend replacement of such panels since our repairs of twisted bars reduces their load caring capabilities. Generally speaking, we do not repair very rusted grating with large bows and grating with holes. You must replace these panels since they impact the safety of traffic.

We also do not repair stainless steel grating with heavy bows. However. we can repair stainless steel grating with minimal bowing that becomes unattached from reversed angular banding. Same principles apply to aluminum grating except that we can not repair twisted aluminum bars.

More importantly, please note that we can improve or modify grating panels with significant areas in good shape to fit smaller pits and smaller trenches in your facility.

Types of metal grating

The terminology of metal grating becomes often confusing for many managers that is why we tend to educate our clients as much as possible prior contacting us. When enquiring for a grating quote please visit the grating steel measurement to find out what we, or in fact any manufacturer needs to know from you. Please visit also bar grating concepts to refresh the grating terminology. Additionally, we recommend to glance our contact page, that suits novice buyers as well as engineers specializing in metal grating.

When communicating with our clients we always try to explain the details in order to avoid miscommunication. Here, on this page, we provide a simple description of metal grating to avoid misconceptions. The types of metal grating section will also indicate and narrow our specialization field and it will create basic understanding about sophisticated world of grating. Additionally, it establishes who you should contact for what type of metal grating and tells you how to contact us.

In order to utilize properly any type of metal grating, one must understand how manufacturers make it. Then the material weaknesses and its strengths will become more obvious.

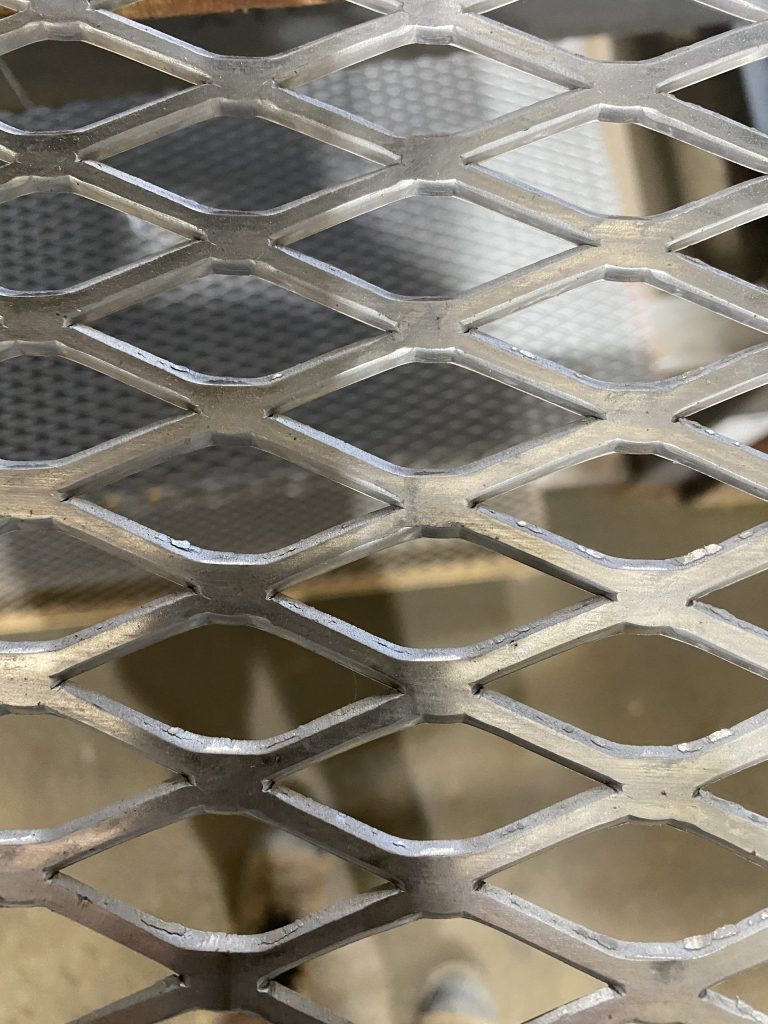

Expanded metal grating

Manufactures make expanded metal grating by expansion of sheet metal. Prior expansion or stretch, the metal sheet is punctured with slits and then the sheet metal is pulled apart or stretched. In the final form the sheet develop diamond shape pattern. Fabricators cut the expanded metal grating sheet easily to fit any application. Manufacturers use variety of metals to produce expanded grating and some unique alloys used for screens can be rather pricey.

Expanded metal grating in non-flattened form has excellent slip resistant surface, however the load resistance is rather mediocre and we do not recommend it for a pedestrian traffic. Even in galvanized form this grating rusts rather quickly due to microcracks.

JW Portable Welding & Repair fabricates safety guards, security fencing and security guards from expanded metal grating. The expanded metal grating suites any security project due to sharp edges, that can be made even sharper. This material is also rather difficult to cut for novice with a poor quality grinder equipped with substandard cutting wheel. The substandard quality cutting wheel vibrates on diagonal diamond shape strands and tend to breaks. That is why it provides relatively good protection against burglars.

The fattened version of expanded metal suits variety of architectural projects. Also, JW Portable Welding & Repairs have done screens from flattened expanded metal grating made from unique alloys that resist chemical reaction.

Terminology of expanded metal

Fabricators use very often SWO and LWO as well as strand size for selection of their expended metal. SWO and LWO determines the size of the diamond opening. The SWO means length of short diamond diagonal, that is the width of a diamond. LWO means the length of long diamond diagonal.

SWO and LWO are important since it impacts directly security and safety of fabricated structures. These diamond openings determine the visibility through the sealed barrier of expanded metal. They also determine how much light will go through the guards. Unfortunately, smaller the openings, the more secure the guards are but less light is going through them and therefore the inside facilities need more light.

Size of strand size is also important. It determines how difficult it will be to cut it by the burglar. The thicker strands resist cuts better and they create greater vibrations while cutting with inexpensive grinders and cheap cutting disk. These vibrations cause breaking of cutting disk when the grinder is operated by a poorly equipped novice.

Manufacturers provide tables to guide you in selection of expanded metal. The expended metal is produced in variety of stainless steels, aluminum and mild steel.

Bar Metal Grating

Bar metal grating is the most popular in the industry since it is the strongest grating per pound and its production is the most efficient considering used material. The bar metal grating, its varieties, and its utilization , lied down JW Investrade Inc. specialization and has prone us to create metalgrating.ca. This metal grating consists of parallel bars that are connected to each other by perpendicular bars to form a panel. Welding is the most popular way to connect perpendicular bars with parallel bars. Other methods to connect these bars include riveting, press locking and close meshing.

Bar metal grating made from steel is the most popular for flooring in the industry as well as for drains. Its drainage ratio to the load is incomparable by any other type of grating. However, drains built from bar metal grating exposed to dynamic loads of multidirectional traffic and exposed to static loads fail often prematurely.

Bar metal grating production

Bar grating production involves one of these processes

- Swaging process

- Dovetail Manufacturing

- Welding process

- Riveting process

Each process impacts the bar metal grating’s strength, weight and utilization period.

Riveted grating

In riveted grating, bearing bars are riveted to crimped flat bars therefore these crimped flat bars maintain the distance between the load bearing bars. Since the crimped flat bars cover significant depth of loading bars, the resulted structure is strong and resists impact and heavy dynamic loads. This grating is very durable and endures stress and pressure. This type of grating is excellent for resisting impact loads characterized by repetitive traffic patterns. The riveted grating concept have heavily influenced our grating weldments concept.

Dovetail grating

Dovetail grating involves one of the oldest technique to join two types of material. Dovetailing is still very popular in construction of wooden houses, furniture, and packaging industries. It involves slotting the two materials and then joining the slots. In case of grating, both load bearing bars and cross bars are slotted. Then the press forces the slotted elements to join together and forms the flat surface on the top. The precisely cut slots with very close tolerances provide rigid fit. This design provide lateral stability and excellent axial distribution. When installing them one has to clearly differentiate between load bearing bars and cross bars. The cross bars do not have as much depth as the load bearing bars.

Dovetail grating seems to be much superior in comparison of welded bar grating for heavy loads. However, its weight is very significant and it requires significantly more maintenance.

Welded bar grating

Welded bar grating involves electro forging process where welding process joins cross bars with load bearing bars. The welded fused connection between cross bars and load bearing bars provides rigidity of the panel. As popular as welded bar grating is, it has also some weaknesses. The electro forging process produces panel structure with welds that are less resistant to vibration in comparison to vibration resistant welds. That is why our improved steel grating contains antivibration welds. The positioning of cross bars on the top increases the impact resistance on top. However, lack of cross bars at the bottom of the panel reduces the resistance to vibration at the bottom depth of the load bearing bars.

Again, our improved steel grating and our grating weldments could have bottom cross bars to resist dynamic loads better.

Swaged grating

Swaging process is usually used to produce swaged aluminum grating where cross bars are pinched in diamond shaped opening in load bearing bars. Such built panel has excellent strength to weight ration, low deflection and maximum safety. The load caring bars are traditionally in 3 shapes: rectangular, I -Bar and T-Bar. The T- Bar increases the top surface most significantly.

Wire Mesh Grating

The wire mesh grating includes wire fabric and wire cloth. Wire mesh consists of rows and columns that intersect each other. Due to its easy cutting and welding, as well as extreme durability, it is very useful for making screens. Fabricators use welded wire mesh for screens due to its excellent rigidity. In welded wire mesh the welding process joins the columns with rows. Other manufacturers produce woven wire mesh. In the woven mesh columns and rows are woven like a fabric. The woven wire mesh is less rigid than welded wire mesh and therefore it requires more structural support.

JW Portable Grating & Repair fabricates variety of light safety guards from welded wire mesh. These safety guards are suitable for safety panels surrounding working stationary equipment as they provide barrier to production crew. Also, welded mesh grating safety barriers are very useful for separation of structures and equipment from the public as it is feasible on the image above. The welded wire mesh is simply incomparable to expanded metal grating in security projects since it is easily cut. Even the utilization of backing strips that help sandwich the wire mesh between to the frame, improves only slightly its resistance to impact.

Perforated Grating

Manufacturers produce perforated metal grating by punching holes of different sizes shapes and edges in metal sheets in order to create desired pattern. They use variety of metal sheets for perforated grating and they include stainless steel, mild steel and aluminum. Most perforated holes are made by rotary pinning or die punching. Lately laser cutting becomes more popular especially in area of screening.

Laser cut perforated grating that can be powder coated or galvanized has become very popular for relatively secure window coverings replacing old fashioned external bars. The designs offered by many artistically inclined fabricators convey character products or services provided by businesses. Additionally, laser cut perforated grating in window coverings not only increases security of buildings for charitable organizations but also signals the organization’s main purpose.

Stainless steel perforated grating appear to be the most efficient for making tread steps from stainless steel.

Grip Strut Grating

Grip strut grating provide the most traction for pedestrians in most slippery conditions. The diamond protrusion in cold stamping is used to produce this superior safety grating. This safety grading offers superior traction while offering excellent drainage and air flow. Grip strut grating dedicates surfaces for liquid draining and pedestrian traffic. The lower surfaces are devoted to drainage and higher surfaces provide excellent traction. Unfortunately, grip strut grating is not very popular in the industry.

Grip strut grating allows for temporary separation of worker traffic from moving water in industrial complexes or food production plants. These type of grating is also gaining attention in Canada among agricultural industries for the same reason.

Compound metal grating

Compound metal grating consists of bar grating and a steel plate grating. Our floor drain cover serves as a perfect example of compound metal grating. Instead of most popular checkered plate we use Q & H at least 3/8″ steel plate and instead of bearing bars we use square tubing.

Manufacturers use also layered bar grating and perforated metal grating. Overall, manufacturers use heavy gauge steel to produce compound metal grading. In our case, we devote extra attention to compound metal grating and we produce this type of grating from thickest walled steel in each category. Such approach also simplify galvanization of our products.