Grate steel for pedestrian traffic ensures the safety and efficiency of pedestrians’ traffic combined with occasional static loads in various environments. Therefore the objectives of grated steel for pedestrian traffic differs significantly from grating steel for vehicular traffic. Although for the novice eyes these two gratings look the same, these two grate steel differ significantly. Grated steel for pedestrians has lower bearing load capacities and slightly lower durability since it doesn’t sustain high stress fatigue caused by dynamic load. It requires increased esthetics factor, and different maintenance practices. Also, it integrates differently into urban landscapes.

On this page, I would like to introduce to you not only to our involvement in grate steel for pedestrian traffic but also to classification of grated steel for pedestrians and also guide you in grating selection. The gained information could also assist you in replacement of some of the damaged panels. I will also mention some of our grating improvement methods to increase grating’s utilization period and integration into urban landscapes.

Our involvement in grate steel for pedestrians

As a mother company of JW Portable Welding & Repairs, we have been involved in repairs and replacement of grating for about 10 years. We have also advised clients on steel grating selection and we have implemented improvements to existing grating. Now, we begin to offer custom and improved steel grating, grating weldments, and trench / drain covers that will fit your needs and extend its utilization time of your grate steel. Although, we specialize in steel grating for vehicular traffic, we also contribute to improvements of grated steel for pedestrians. If you require more insight into grating for mezzanines and catwalks, or machine guards than please click here.

Repair of supporting structure for grate steel

Fortunately, within our mobile welding services, we repair the missing rusted support and we install new support consisting from new steel angles, and channels. The panels for pedestrian traffic are much longer and therefore heavier and they bend over time when support is insufficient. Therefore repairs of their support without positive attachment to the the support could result in mediocre effects. Attachment of grate steel panels to their support is paramount for pedestrian traffic.

In factories and in many multilevel older houses there are outside stair cases with rusted columns. The rust damages of the column usually affect up to 18 inches of the column’s bottom. In many instances, it is enough to replace the bottom of the column instead of costly replacement of the whole column. In fact we have developed a procedure to replace the bottom of the column without a crane support.

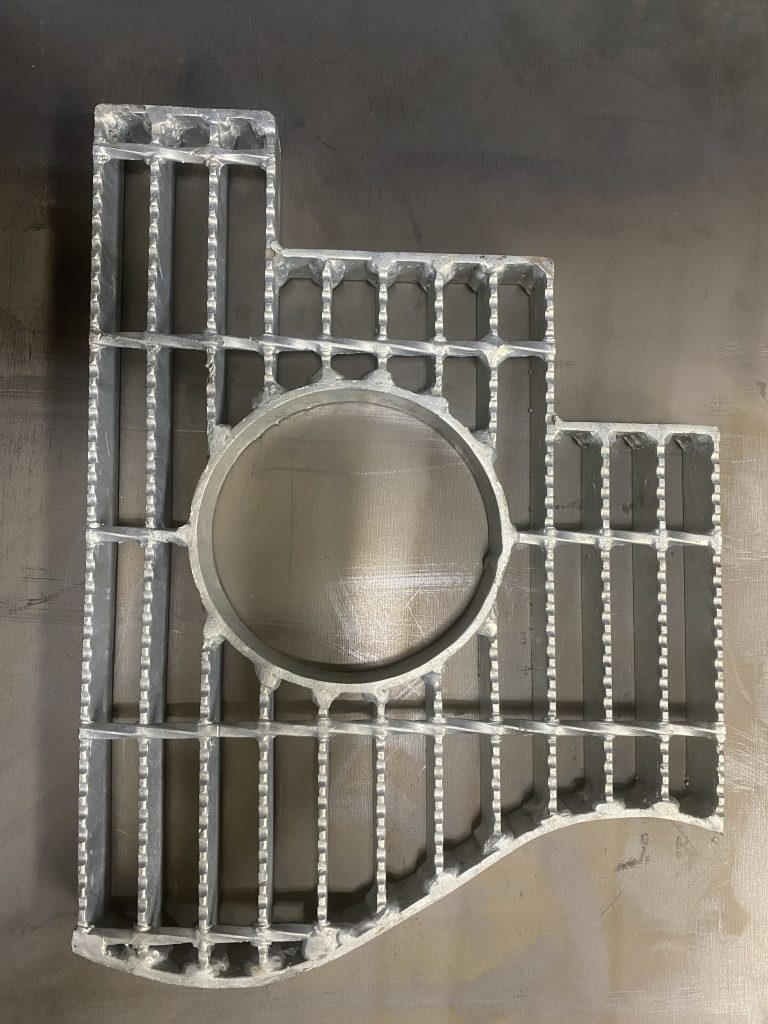

Finesse shape of grate steel panels for pedestrians

Being able to form the shape of the edge of banding to the shape of the structural support is crucial for grate steel panels in shopping centers, and dense urban centers. Many of these panes have visually attractive shapes, and we not only can cut these shapes in panel’s depth up to 4 inches, but also we are able to conform the banding to these complicated shapes. Most importantly, however, which is a very unique, we are able to weld the banding with antivibration welds to each bearing bar.

In this way, we are not only conform the whole panel to urbanistic design but also we improve the strength and impact resistance of these strange looking panels. These strange looking panels are especially popular in industrial settings where they have to follow the contour of heavy machinery. Grate steel panels that follow the contours of heavy machinery allow workers to access the heavy machinery without using ladders or elevated work platforms.

Improved by us panels in irregular shape, offer more supporting flexibility in industrial environment. You can place supporting structural steel in areas of fancy banding since our welded banding bars are load bearing bandings. Additionally, we can create openings that allow for protrusion of different elements through the surface of the grated steel panel. The banding welded inside the opening exceeds traditional standard of the industry.

We ship improved grate steel panels Canada wide and we are ready to ship to US. Please contact us for quoting and click improved grating. Please keep in mind that will need a template to produce the unusual shape grate steel panel.

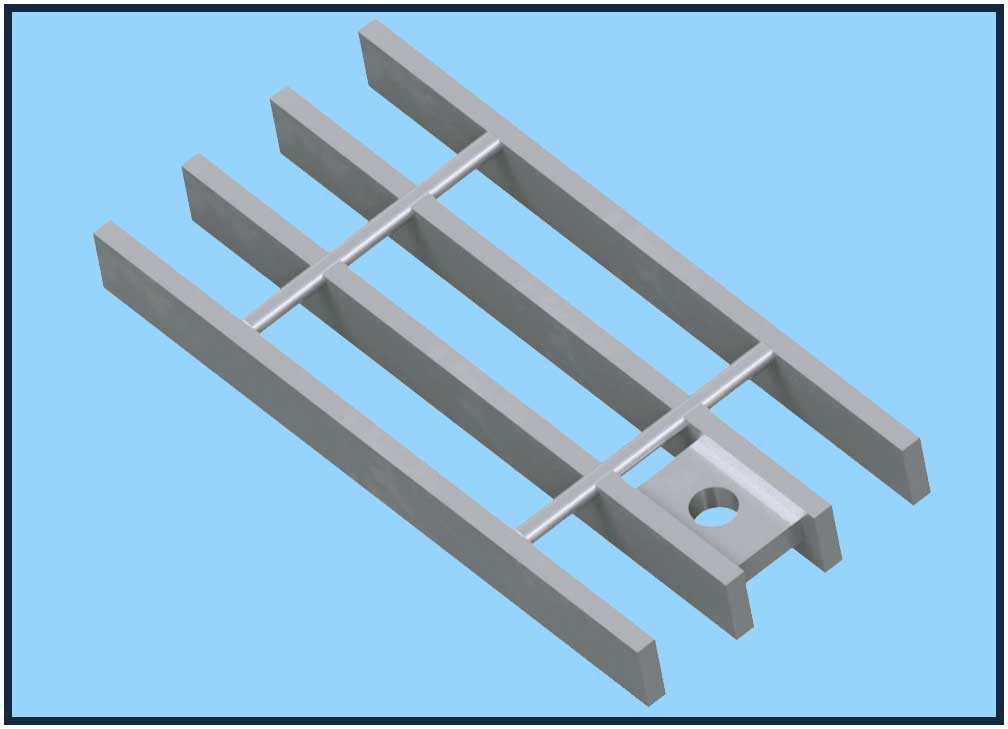

Removable grated steel panels with reverse angle frame.

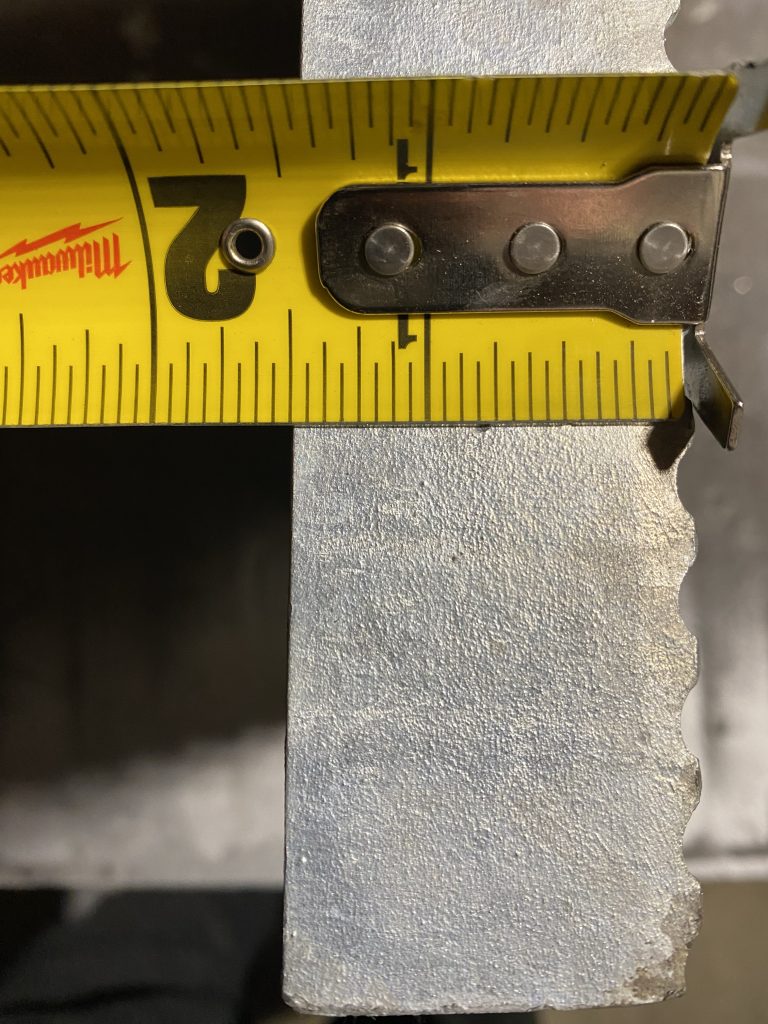

We produce removable grated steel panels for pedestrian traffic with frame made from reversable angle. The reversable angle frame allows for placement of the panel on concrete trench without any structural support. The reversed angle structure overlaps the opening made in concrete and it is sufficient for pedestrian load. The heavy structural angle has a thickness of 3/8″ inch and therefore pedestrian will feel the small step out of 3/8″ from the walking level.

Please refer to grating steel measurements for precise measurements of gaps with a tape measure. This page will also explain to you what we need to know prior quoting your project.

Some old long trenches also require the panels with reversable angles since they do not contain traditional angle steel support. The 2 external panels, one on the right and one on the left with 3 reverse angles and 1 strengthening side. The middle panels have 2 reversed angles and 2 strengthening bars.

Other involvements

We have built custom devices to lift small and medium size panels from trenches’ angular support. We can lift them even if they are very heavy and seized up. After lifting off the support, the forklift can transport these panels or crane can lift them.

Panels on mezzanines, catwalks and in staircases are permanent and removal of these panels is often difficult. It sometimes involves cutting them into smaller sections with torch. We provide the removal panel service within our mobile welding or portable welding services within area of 150km radius from London, Ontario.

Installation and replacement of grate steel for pedestrian traffic

While reading this section please have the Bar Grating Basic Concepts open for quick reference of terminology and glance of sketches.

The engineered drawing usually determines installation of new grated steel but it does not determine trade practices of installation. It also does not determine most practical attachment methods, and anti-slippery technologies. In fact, forwarding certain suggestions to your professional engineer could improve pedestrian comfort and safety. Additionally, it could make your grating more pedestrian and installation friendly. More importantly, I would like to make you aware of limitations of grating for pedestrian traffic in regards to its maximum load and durability. Therefore let me introduce to you basics of terminology, practices of installation, replacement and fitting it to urban environment.

Grate steel support structure

Grated steel for pedestrian traffic requires perfectly level support. These panels leveling must be perfect for pedestrians to walk comfortably disregarding the place of their installation. Contractors install them in factories on mezzanines, on bridges, on trenches and pits closed to walkways. Surely, during new construction the leveling suitable for pedestrians is not and issue. However, in many trenches and pits closer to city’s center, the support deteriorates faster than grated panels. Then problems appear. Same happens within dense urban shopping centers. Although, the deterioration of support does not create a safety hazard, the rocking panels definitely turn attention of pedestrians.

Depth of bearing bar

Depth of bearing bar is one of most important parameters when installing new and replacing old grated steel. In concrete trenches it is the vertical distance between top of the angle toe and the bottom tow on the root side. In mezzanines, it is a thickness of the grated steel panel. Please do not confuse it with thickness of the bearing bar.

Pedestrians should not notice the elevation distance between concrete and the grated panel of the trench. That is why the panel’s top surface should have the maximum elevation of the surrounding concrete. The panel’s top surface should not be higher. Therefore, grate steel panels for pedestrian traffic must not have depth higher then the concrete due to tripping hazards. Whereas, some panels for vehicular traffic could stick out a little to accommodate greater demand for increased load capacity.

In mezzanines and in stairs cases the depth of bearing bars also relates to comfort of pedestrians. The areas of stepping on the grated panel and stepping out of grated panel follows strict regulations. Additionally, the proper engineering corrects the potential issues regarding tripping hazard.

The most popular dimensions for depth of bearing bars for pedestrian traffic is probably 1 1/2″, then followed by 1″ and 2″. Less popular are 3/4″, 1 1/4″, 1 3/4″. The depths above 2″ are rather rare.

Thickness of bearing bar

The next important parameter is thickness of the bearing bar. Most manufacturers produce grated steel for pedestrian traffic in bearing bar thickness 1/8 or 3/16″.

That is why when I notice 3/16 bearing bars on trenches used by vehicles, I know that we will find issues. Certainly, some of these panels can handle occasionally low volume of light traffic. However, they cannot handle heavy traffic causing high dynamic loads. As I said, there are panels suitable for occasional vehicle traffic but I always respond to such argument with question, define occasional?

The grate steel panels with bearing bar thickness of 3/16 used for sidewalks suites pedestrian traffic very well and suits occasional vehicular traffic on smaller spans. Especially in locations where only one wheel goes on the grating and the other wheel drives on concrete or asphalt.

Bearing bar spacing

Bearing bar spacing is the next important parameter of grated steel. The bearing bar spacing is the distance between centers of bearing bars. Bigger the bar spacing in the panel less bearing bars are in a panel. These larger spaces make walking for pedestrians less comfortable. Bearing bar spacing is measured in 1/16″ increments but some grated steel has bar spacing measured in 1/32″

Bearing bar spacing plays extremally important role for passenger traffic and for maintenance programs. Panels more convenient for pedestrians become heavier to the point of impossible manual removal. Therefore, maintenance workers use variety of mechanical devices to lift these panels.

Mesh grating

Mesh grating refers to denser grating with more bearing bars in the panel. The mesh grating includes grate steel with bearing bar spacing of 15/16, 13/16, 11/16, 10/16, 13/32 and unbelievable 8/16 and 7/16. The term “high heel” grated steel applies to panels that are save for pedestrians walking in high heel shoos without breaking their high heels.

Please note that distance between bearing bars is determined by two factors, bearing bars spacing and the thickness of bearing bars. The bearing bars spacing is the distance between centers of bearing bars. The panels with the same bearing bars spacing but with thicker bearing bars have distances between bearing bars smaller. This fact plays important role not only in pedestrian traffic but also in filtration industry.

Cross bars and their spacing

Measuring cross bar spacing is another parameter. Cross bars are elements of steel bar panel that are going perpendicular to bearing bars. In case of grate steel for pedestrian traffic these elements unusually consist of round steel or twisted rods for better friction. These elements are not responsible for caring the load but for maintaining the structural integrity of the steel grading. If you see on your existing panels’ cross bars in form of the flat bar than these panels are most likely for vehicular traffic. These steel panels with flat bars have higher structural integrity. They suit well the vehicular traffic.

Span of grated steel

The span of grated steel determines the length of panels and it is the distance between support on opposite sides. The span of grated steel for pedestrian traffic is generally mush longer than span of panels for vehicular traffic. The panels for pedestrian traffic simply handle lower loads and are exposed to much lower fatigue. Therefore engineers are less restricted by these factors in determining the maximum clear span between supports.

The span of panels for pedestrian traffic does not have to go along the width of the trench. Some wide trenches have structural steel support in the middle to accommodate the limited width of the panels. In such trenches, we can use panels length to the their full extend.

Same concept applies in industrial environment in construction of mezzanines and catwalk. Engineers tend to use the length of grate steel for pedestrian’s traffic to full extend. They place supports for the grated steel panel in regular distances under the panel. Therefore sections of catwalk or mezzanines are very heavy and they are not suited for manual installation.

Majority of panels for vehicular traffic in secondary market can be installed manually since they have low span. Certainly, panels for vehicular traffic in prime infrastructure projects such as bridges are much, much more heavy.

The span of panels for pedestrian traffic is much longer. These panels become much longer and much, much heavier, therefore workers approach these panels differently during their installation.

Handling of panels for pedestrian traffic

Handling of panels for pedestrian traffic is different than panels for vehicular traffic in secondary market. Panels for pedestrian traffic are longer, have more bearing bars and are much heavier.

The long panels should be transported on long semitrailers with proper wood cribbing to eliminate twisting and bending. The workers should use forklift with widest spread of forks for unloading these long panels. It is also a good trade practice to secure the panel to forklift’s forks with a good quality C-clamps since steel on steel slides very well even at slight vibration.

Lifting the long panels with the crane is always the challenge since their rigidity is the best while laying down. The lighter type panels are very flimsy and they bow very easily. Even when lifting 3 or 4 of these long panels separated by wooden cribbing, you could signs of flimsiness. Therefore workers should use proper rigging devices to avoid damaging these panels during the lift. Such rigging devices as combination bar spreader and four legged lifting chains, could become very useful.

Precise positioning of long panels on their support increases the pinching hazard. Workers should never try to initiate movement of panels by pushing them or puling them with their hands even when wearing good quality gloves. Remember always to use suitable steel prybars for additional leverage and keeping distance from these long panels.

Weight of these panels

Due to use of dense bearing bars and significant lengths the panels for pedestrian traffic could become very heavy. Panel with 19/32 bearing bar spacing, and 3/4″ x 1/8 bearing bar weights 8.36 lbs./sq.ft. So panel 6 feet long by 3 feet wide will weight 150.48lbs. Same type panel with bearing bars 1 1/2″ x 3/16″ weights 21.26 lbs./sq.ft. Therefore same panel 6′ x 3′ will weight 382.68lbs. And, remember there are type of sidewalk panels with bearing bars 2″ x 3/16″, 2 1/2″ x 3/16″ and even 3″ x 3/16″. Panel with 3″ x 3/16″ bearing bars, and same dimensions would weight 730.80 lbs. And remember this was just 6’x 3′ panel, so relatively small.

Panels for pedestrian traffic in trenches or pits are usually semi permanent and non- removable. However, if panels must be removable for rare maintenance inspection, they can be engineered lighter. We tend to reduce the span and go along the width of the trench with the span therefore we treat these panels for pedestrians as we treat panels for vehicular traffic.

Distance between panels

Distance between the panels and the steel angles that provide the support could be about 1/8″ to 1/4″. Definitely larger gaps are more popular, especially in industrial environment and when you regularly must clean these panels. In trenches, the dirt accumulates in this gaps between steel angle supporting the panel and banding and smaller gaps are more difficult to clean. Additionally, rust accumulates there if you have nongalvanized steel grating and then these panels are extremally difficult to clean.

In industrial environment on mezzanines, catwalks, and stair cases the distance between the panels should also be at least 1/4″. Although, many project managers prefer gaps of 1/2″ for easy installation.

Banding

Banding plays a significant role in the strength of grate steel panel, but it does not play a significant role in pedestrian panels. The banding flat bar is position perpendicularly to all bearing load bars. Each panel contains 2 bandings, but in case of panels for pedestrian traffic they usually are not load bearing bandings. These bands are trim bands and they are usually welded at both ends and in the middle of the panel +/- 5″ of center. This is a NAAMM standard

Much more important is banding’s draining functionality for these panels. Therefore banding usually do not reach the depth of bearing bars. In this way we create gap between groove formed by bending and steel angle support.

In industrial environment attachment of kickplate is sometimes beneficial. Kickplates are welded to the pedestrian’s panels in the same fashion as banding. However, it is mush more convenient to attach kickplates to handrail’s posts than install grate panels with the kickplate already welded in. However, it is up to engineer to decide what method is more preferable.

Anchoring

Anchoring of grate steel for pedestrians plays more important role than anchoring of panels for vehicular traffic in secondary market. The more permanent nature of panels for pedestrians dictates permanent or less flexible attachment of panels to their support.

Permanent panels are welded to their support at the middle of the panel and at each intermediate support. Additionally each panel is welded to its support at all 4 corners at 6″ from the edge of the panel. This is another NAAMM standard. These panels are permanently attached to their supporting structure.

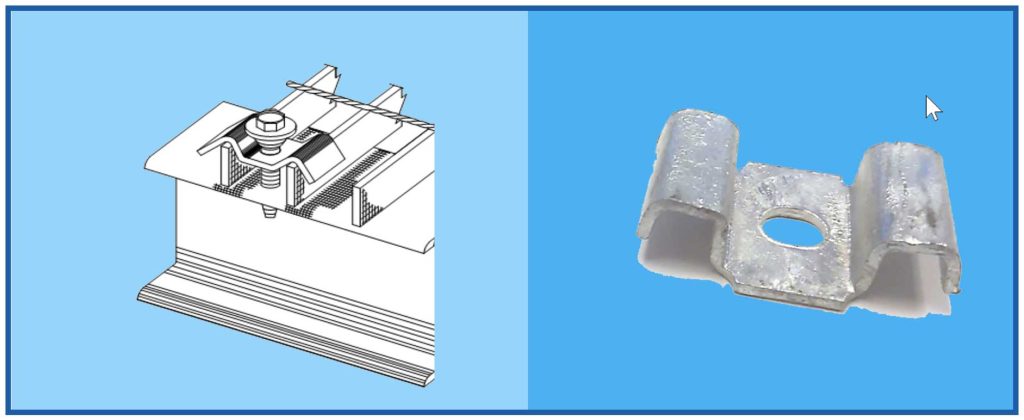

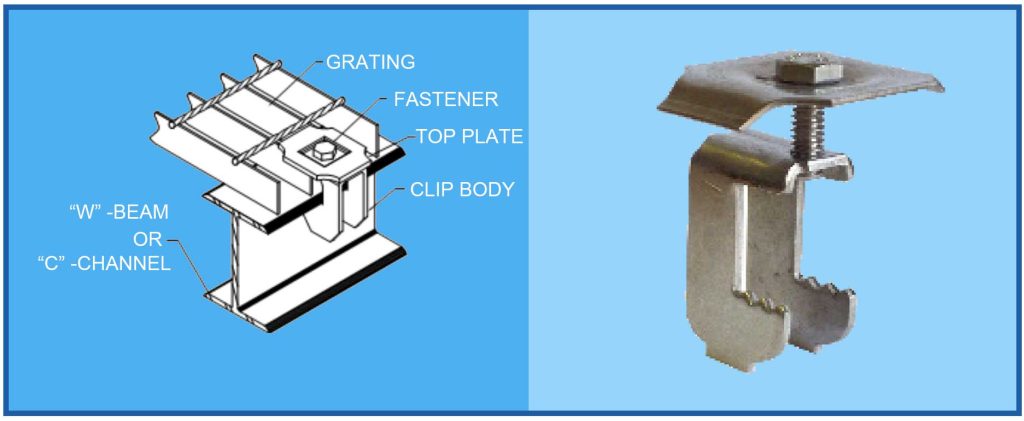

Saddle clips

Saddle clips provide semi-permanent attachment of panels to the supporting structure. Their location is the same as welding pattern described above. Fasteners are 1/4″ diameter and nuts are located on top. Therefore one worker inserts the bolt from the bottom side of the supporting structure, and the other worker tightens the nut on top of the grate steel.

Weld lugs

Weld lugs located in space between the bearing bars also provide semi permanent attachment. Same pattern of attachment is used as in two above examples. That weld lugs do not provide as much flexibility as saddle clips. They provide excellent anchorage for grate steel panels for pedestrian and vehicular traffic.

F clips

F clips also provide semipermanent attachment for rather lighter grate steel and they do not require any drilling since they utilize Tek screws.

G clips

G clips are for semipermanent attachment of panels for pedestrian traffic that are removable. Installation of G clips does not involve making holes in structural support. Therefore G clips save labor cost and only one worker instead of two workers is able to install them.

Please note, numbering of panels and marking their orientation allows for easier removal and easier installation. Please remember also that these panels not only bend but also have discrepancies of dimensions therefore gaps between them are allowing for easier installation.

Panel’s surface

Grate steel panels for pedestrian traffic can be serrated or flat. Definitely serrated bearing bars improved friction and reduce trip hazard but they are more popular in industrial environment.

In the urban centers in large cities other methods are more popular that improve slippery top surface of grate steel panels. Many manufacturers offer relatively new grip technology that makes the slip resistant surface on top of the bearing bar. This technology works very well in wet, dusty and oily environments. Also, it provides better results than flame spray or any friction increasing paint applied by brush.

Please note, if you are planning to galvanize the grate steel panels after application of grip technology, be aware that galvanization may damage the increased grip surface.

Riveted Grating for Pedestrians

Riveted grating stands out in for its reliability, durability and comfort and it is recommended by engineers for first priority infrastructure projects. Putting aside reliability and durability of riveted grate steel, lets take a closer look at comfort.

Riveted grate steel in industrial environment

In industrial environment, comfort plays secondary role , but safety does not. Workers walking on riveted grate steel experience superior slip resistance that minimizes slipping hazard even when working in worst conditions in wet and oily environment. Riveted grating has excellent drainage.

The serrated reticulated bars that are riveted to bearing bars provide excellent anti slippery protection. These serrated bars are are riveted at highest points, and these higher points provide very aggressive anti slippery protection. Please note, work boots do not last long on riveted grating.

Also, the trapezoidal shape of these reticulated bars adds up friction for walking workers. However, if you try even once to go with your knees on this grate steel, you will remember this bad, bad idea for months.

Riveted grate in urban environment.

Use of riveted grate steel in serrated form is rather questionable in urban environment. The general public does not wear work boots since we wear shoes and some pedestrians wear high heels. Our shoes have much thinner soles and walking with regular shoes on riveted grates is not comfortable at all.

Believe me, I have tried it a few years ago and I still regret this unpleasant experience. Wearing high hills is out of question. And, children should not walk on it either for reason mentioned above and due to possibility of serious injury if they fall on it.

Flat riveted grate steel is perhaps slightly better. This type of riveted panels was used at beginning of last century for pedestrians crossing steel bridges. I was fortunate to walk on it in Europe fairly recently and walking on it in shoes was fairly comfortable although you could still feel it. Grip was sufficient. Saying it, walking on it in high hills was out of question and child falling on it would suffer severe injuries.

Welded vs Pressure Locked, Grate Steel for Pedestrian Traffic

Majority of grate steel for passenger traffic is covered by bar grating. So let’s evaluate welded vs pressure locked grates for pedestrians. We probably should consider anti-friction, comfort, versatility, durability, cost, corrosion resistance, and aesthetics.

Anti-friction

Both types of grate steel offer serrated grating and both offer comparable surfaces in terms of thicknesses of bearing bars. However, it seems that pressure locked grating is more preferable for grip technology especially in mesh categories.

Welded grates have the cross bars sticking out more significantly than pressure locked grates. Therefore, without considering ani-friction technology this category goes to welded grates.

Comfort

The mesh category in both types, welded and pressure locked, is designed for pedestrian traffic. Smaller the distances between bearing bars and flatter the top surface, the panel becomes more comfortable for pedestrians. Due to the fact that high heels grating is available in 7/16″ and 1/2″ of bearing bars spacing and due to flat surface pressure locked technology makes this grating more preferable.

Versatility

Many manufacturers have started to reduce versatility of welded grates while they increased versatility of pressure locked grates. And now, pressure locked grates are available in mesh density or even high heels density.

Durability

The durability of pressure locked grates is slightly lower than welded grates but pedestrians or occasional vehicular traffic does not demand so high durability since they do not cause so high fatigue stress.

Cost

The welded grating seems more cost effective than pressure locked grate steel. The manufacturing of pressure locked grates involves more intricate processes than welding. However, the cost difference is not as great.

Corrosion resistance

Corrosion resistance of welded grate steel is much lower than pressure locked panels especially in harsh Canadian winter and presence of salt.

Aesthetics

Without any doubt the pressure locked grate steel is more visually pleasing and it is used for many architectural designs for its clean modern look.

Conclusion

Ultimately, the choice between welded steel grating and pressure-locked steel grating for pedestrian traffic depends on the specific requirements of the project. Including potential occasional vehicular traffic, aesthetic preferences, and environmental factors.

The pressure locked grating’s popularity in urban centers is undisputable. Also, its greater resistance to rust in bare form in Canadian climate is superior. And greater architectural appeal would lead me to declare pressure locked grating more preferable. However, ultimately the decision is yours.