We produce steel metal grating custom structure weldments to replace grating panels that are being damaged most often in grating area. We also replace the old drain covers with our custom structure weldments due to insufficient in particular conditions resistance to load of traditional grating or even our improved grating for vehicular traffic.

Some grating areas sustain severe damages in specific panels in very specific locations where the dynamic load and severe impact exceeds fatigue resistance. In fact, to be more precise the concentrated fatigue damages do not affect the whole steel metal grating panel. However, the concentrated fatigue damages affect a specific spot on the panel. Nerveless, you are forced to replace these specific panels very often.

Replacement of traditional grating with improved grating

Some businesses in specific industries are replacing these specific steel metal grating panels every 3 or 4 months. These specific panels are located in known to them locations and in these specific locations steel metal grating does not last long. To make things worse, the damage originated in specific spot in the panel starts spreading quickly. Then soon the small initial damage gets bigger and bigger. Finally, the damage gets so big that the risk of grating failure increased dramatically. …And, the crew replaces the damaged steel metal grating panel with the new panel made from the same grating type. I find this method to be very peculiar. Then again the vicious cycle begins.

Each time the replacement process makes the whole structure nonoperational which complicates shipments and production processes. Loading and unloading becomes impossible when the vehicles enter the soft spot created by damaged steel metal grating panel. Nobody knows when the panel will give in and the accident happens. The crew monitors the spot daily and estimates the time for next panel replacement. Such maintenance approach is not only costly but also inefficient and assumes certain risks of equipment failure.

Replacement of traditional grating with custom made weldment

Over the years our vehicles have become larger and heavier and our infrastructure have got older and less perfect. If you face difficulty to fit a new drain cover to the old drain, or the depth of the old panel is too shallow for your heavy vehicles than completely custom grating weldment is your solution.

Repairing, customizing, improving steel metal grating

We have been repairing, customizing, improving steel metal grating panels for 10 years now. We are JW Investrade Inc. the mother company of JW Portable Welding & Repairs and we have been dealing with steel grating failures for years.

At first we have started with repairing the grating panels locally in London, Ontario and in surrounding area. Our repairs included welding the cross bars to the bearing bars and straightening the bent bearing bars. As straightening bars is and exiting and interesting process, the welding cross bars is very boring and repetitive task. Here is more about our repairing process.

When we could, we have always tried to improve the the steel metal grating panels to give our clients more utilization benefit. These improvements included welding much thicker banding or welding square rods to the bottom of the bearing bars as bottom cross rods. We have also used many strengthening procedures for bearing bars in the middle of the panel and in the rim as well. In meantime, we have learned how to properly weld the banding with our anti – vibration welds. Also we have learnt how to cut the steel grating precisely. However, we could not do our improvements on old panels since they were too bowing in variety of directions. Additionally, in majority of cases they were also too rusted. That is why we had to resort to new panels that we have started to improve. You can find more about our improved steel metal grate here.

Innovation process

Certainly, at beginning we were not improving all panels in the grating area. Definitely, we were focused on specific panels that were being damaged most often. We knew that our clients will sacrifice the unified look of grating area as long as they do not have to change grate panels in specific location so often. This thought has laid the foundation for our innovation process.

The innovating process has led us into specific panels’ customization and/or improvements based on different steel material used and different welding procedures while maintaining the structural concepts that has been proven in tough conditions. Most importantly we have realized that the structure of steel metal grating must be similar to dovetail or riveted grating to sustain the extreme fatigue forces. This thought laid the foundation for design and production/fabrication of our custom steel metal grating weldments.

3 reasons for our custom steel metal grating weldments

The steel metal grating weldments was the next reasonable step in dealing with notorious failures of some panels. The customization of new grating panels have increased the useful life of steel metal grating. Nevertheless, still some panels were failing prematurely.

Firstly, these improvements of steel grating panels have changed the overall damage characteristics and significantly increased the life span of these panels. It is true that these cracks in improved panels were much smaller and they have spread much slower. Also, these cracks did not grow so deeply so quickly and the whole structure have maintained its rigidity much, much longer. However, these cracks still existed prematurely. Therefore this success was rather partial and not good enough to satisfy us.

Secondly, we could not get many steel grating types quickly enough due to manufacturing backlog during the busy season. Our clients could not wait 6 – 8 months for their special orders. Additionally, wastage and therefore cost of some special grating types was rather significant. If we were just producing one or two panels from the 24 feet long material of particular type, the whole operation was not efficient enough. ….And the cost was too significant.

Thirdly, our improved and customized panels have contained metal steel grating manufactured by others. Therefore, we’ve had to conform to load and impact data per size of grating for particular type of grating. Most often, we are dealing with depth of bearing bar restriction, therefore the available choices for load/impact are still very slim.

Due to these 3 main reasons, we have decided to innovate even more. We have started fabrication of steel metal grating weldments based on leverage principle of riveted grating. The grating weldments are much superior to mass production in most popular types and sizes.

Engineering methodology for the need of grating weldments

Our engineering methodology involves secondary data provided by NAAMM and manufacturers of standard steel grate supported by our empirical methodology. Our empirical methodology involves:

- analysis of cracks in cross bars and bearing bars,

- progress of bow deflections, and

- progress of twist deflections.

Primary research also has involved measurements of impact and vibration. We have used slow motion videos to confirm our findings.

Secondary data provided by NAAMM

We always start with secondary data provided by NAAMM and manufacturer. Therefore we start with NAAMM guidance related to static load and impact of 30% of static load. Then we modify their data according to our proprietary formulas. Then we arrive with more realistic dynamic load and perhaps more excessive impact. Finally, we reduce the suitable span for maximum dynamic load of particular type of steel metal grate.

When our reduced suitable span for maximum dynamic load, JW Span For Maximum Dynamic Load is too small in particular grating type and in particular bearing bar size then we recommend grating weldments instead of our improved grating

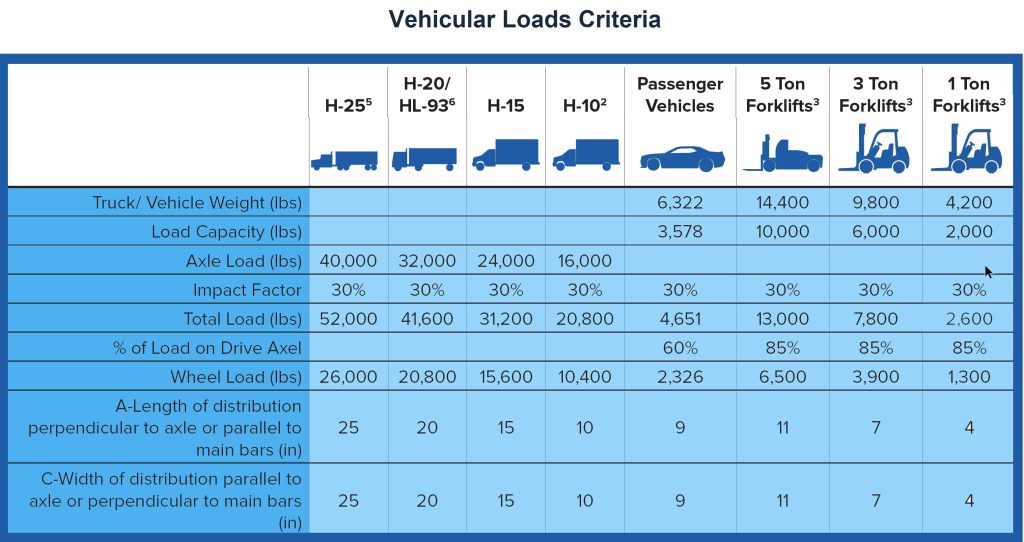

First we need to know client’s traffic type

Once we know what kind of traffic enters the client’s facilities then we can find out following

- Total load

- Wheel load

- A length distribution

- C width distribution

Primary research of client’s damages

Next, we receive primary research data from client regarding deflections, crack distribution, and twist. Our clients also must provide suitable information regarding steel support for their grating. We also identify the client’s old steel metal grate to find out the Maximum Clear Span for the old panel. Then we put their data into our formulas.

Secondary data for steel metal grating provided by manufacturer

Then we find out from our manufacturer the type of grating panel that will suit the client the most. Certainly, we only deal with manufacturers that produce quality panels in types we require. We call at least 4 manufacturers. Then we compare the Maximum Clear Span of proposed type of panels for particular bearing bar size.

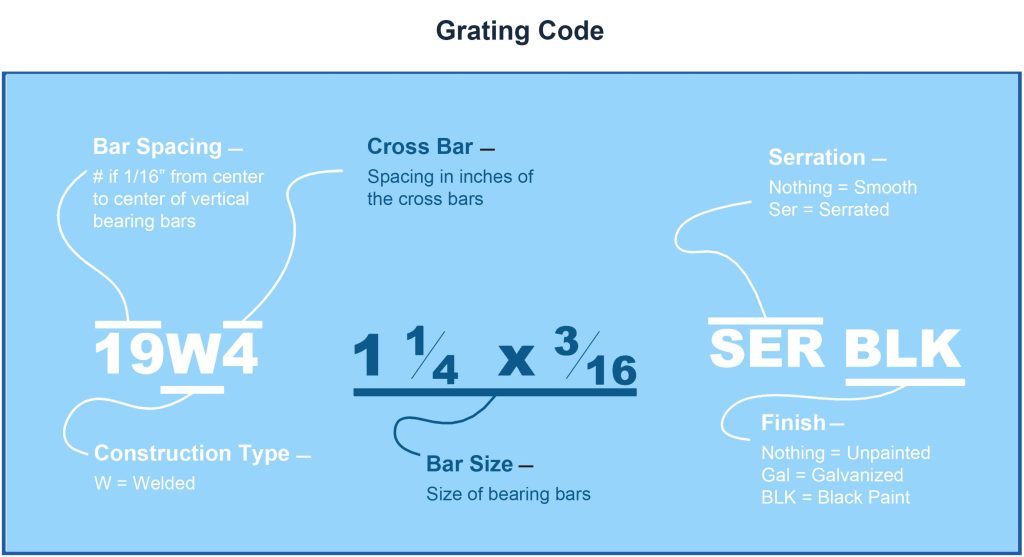

In following example we will compare 15HW4 grating to 30HW4 with bearing bar depth of 1 1/2″. Certainly, this example simplifies the situation since each manufacturer usually provides 2 proposals. Therefore, we usually receive 8 proposals of grating types in variety types related to manufacturing processes.

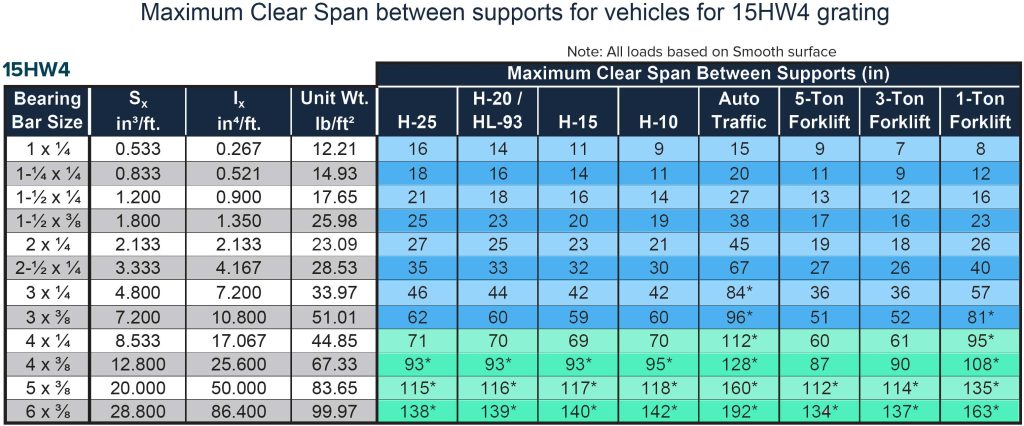

First candidate, 15HW4 grating

The secondary data provided by manufacturer looks similar to image below. The 15HW4 is the portion of steel bar grating telling us the bearing bar spacing and cross bar spacing.

When you look at bearing bar size column, you will notice 1 1/2 x 3/8 and 1 1/2 x 1/4. Then look at auto traffic for these bearing bars you will find 38″span and 27″span respectively. We would chose the bearing bar with longer span in our analysis.

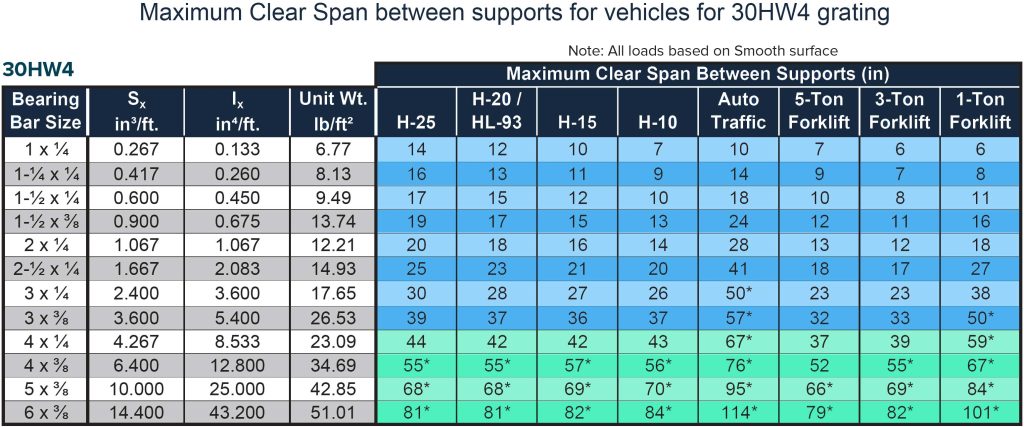

Second candidate, 30HW4 grating

Now, lets compare the same data for 30HW4 grating. When you look at bearing bar size column, you will notice 1 1/2 x 3/8 and 1 1/2 x 1/4. Then look at auto traffic for these bearing bars you will find 24″span and 18″span respectively.

Obviously, the 15HW4 grating provides longer Maximum Clear Spans with bearing bar 1 1/2″ x 3/8″ . This grate is superior to all of them.

We usually continue to the next step with 3 proposals of best grating types. These 3 gratings offer the longest Maximum Clear Spans

Final calculations clarifies the steel metal grating winner

In final step we select the winning type of grating in particular bearing bar size. And, we establish the second the grating type on second place. These gratings have reduced Maximum Clear Spans based on our empirical formulas. We assign them JW Maximum Clear Spans which are much shorter spans than Maximum Clear Spans provided by Manufacturer.

The JW Maximum Clear Spans are usually longer than the real client spans. If JW Maximum Clear Spans are longer than project’s spans, we include these gratings in our proposal. The client selects the best grating type and we will then improve this grating to meet our client’s demanding environment.

However, if JW Maximum Clear Spans do not exceed real client’s spans then we clearly communicate this fact to our client. Next, we intend to recommend our grating weldments into our proposal instead of improved grating.

Our steel metal grating weldments

Our steel metal grating weldments differ from ordinary steel grating in steel components used, and increased volume of welding. Also, we have added some additional elements not seen in traditional steel metal grating.

Steel structural elements of our steel grating weldment for depth 2″ – 3″

Instead of bearing bars we use hollow structural tube square (HSTS) or hollow structural tube rectangular(HSTR). Certainly, we use only these elements in most thickest walls in each category. We call them bearing tubes.

Instead of cross bars we use once again HSTS’s or HSTR’s in the same sizes as bearing tubes. We call them cross tubes and we position them every 3″, 4″, 6″, and 12″ as it will depend on the customer’s situation. Also, we can position them irregularly. For instance, places directly under the wheel will feature more dense pattern of cross tubes to form better support for dynamic load.

Our banding bars are much thicker and range from minimum of 3/8″ to 3/4″ solid flat bar.

The round 3/8″ top rod is welded to every second bearing tube in the middle of the top surface. We call it simply top rod. Please note* not all models of our steel grating feature top rod. The higher load models do not feature the top rod.

At the bottom of the panel there are additional cross bars in form of 1/2″ x 1/2″ square rods welded to every bearing tube. We call them bottom cross bars.

All around full welds

All steel grating weldments consist of bearing tubes and cross tubes that are fully welded with welds going around each joint. We weld bottom cross bars with two opposite welds on each bearing tube. And, we weld the top rod with stich weld consisted with apposite weld passes.

Structural steel elements of our steel metal grating for depths 1″ to 1 3/4″

Again, instead of bearing bars we use hollow structural tube square 1″ x 1″ or 1 1/2″ x 1 1/2″ (HSTS), with most thickest walls in each category. These are our bearing tubes.

Instead of cross tubes as in above example, we use traditional top cross bars in form of 3/8 round rod. This feature has been developed by our repair services and it has been proven to work very well.

Our banding bars for bearing tubes of 1″ to 1 3/4″ ranges from 1/4 to 1/2″.

At the bottom of the panel there are additional cross bars in form of 1/2″ x 1/2″ square rods welded to every bearing tube. By installing the bottom bars we have sandwiched the much smaller HSTS’s between bottom cross bars and top cross bars. Such boxed structure increases additionally dynamic load and impact resistance.

Again, all elements of steel metal grating weldments including bearing tubes and banding are fully welded with welds going around each joint. We weld bottom cross bars with two opposite welds on each bearing tube. And, we weld the top cross bars in the same style.

All our grating weldments are hot galvanized from inside and outside

Hot galvanization process protects our grating weldments against the rust attacking external surface in wet and salty environmental conditions. As we have assured our clients that our grating weldments will sustain our harsh Canadian winters, we had to also make sure that the internal surfaces of hollow tubes will not rust either. It is a common knowledge that hollow tubes rust from inside and capping it will not prohibit development of rust inside the hollow tube.

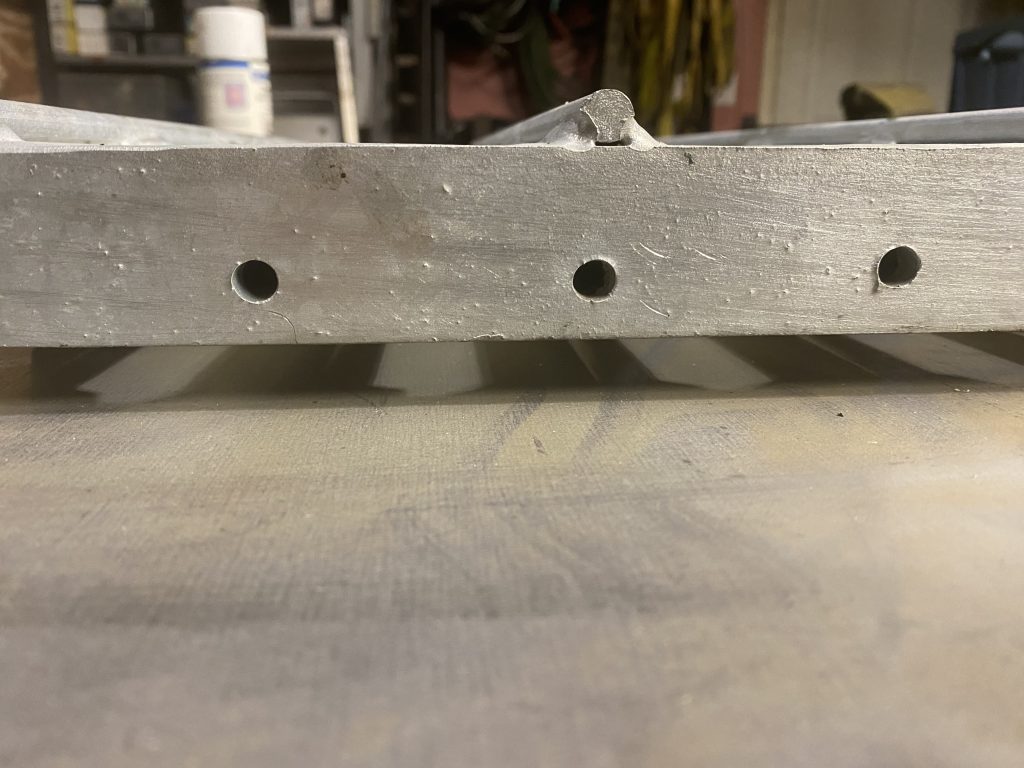

That is why we have reached to our friends form hot galvanization business for some advice and suggestion for galvanization of inside walls in hollow tubes HSTS or HSTR. Our friends from hot galvanization business have recommended drilling at least 2 holes in each hollow tube, one hole in one end and the second hole in another end. These holes allow the hot galvanization process cover the inside walls of every tube.

High impact/load for small depth grating

Most of our secondary market uses steel metal grating up to 2 1/2″ depth. Therefore, it is very difficult to find at 2 1/2″ depth or smaller a superior impact/load resisting grating type among presently manufactured types. In fact, the resistance to fatigue becomes even worse at 2″ depth and 1 1/2″.

For the same weight, the hollow tube will be stronger as the material is further from the center, it can work with a grater moment to resist overall bending. This remains true until you get to localized buckling from very thin walls.

Therefore 2″ x 2″ x 0.250 HSTS with weight of 5.41 per foot will resist a static load much, much better than 3/4″ x 2″ flat bar that weights 5.10 per foot. However, 2″ x 2″ x 0.250 HSTS provides a flat coverage of 2″ in comparison to 3/4″ of flat bar. Therefore, it becomes 267% more efficient. Certainly, in the above calculation we have assumed 3 bearing bars with thickness of 1/4 and bearing bar spacing of 20 that is 20/16.

The cross tubes welded through the whole depth to the bearing tubes spreads the concentrated dynamic load to more bearing tubes. These cross tubes spread load better than any type of crossbar for bearing bars in any traditional steel metal grating. Therefore more bearing tubes participate in carrying the load.

The sandwich effect between top cross bars and bottom cross bars for smaller depth tubes stabilizes the distance between the bearing tubes. In this way, it allows for spreading the load among more bearing tubes.

Extremally high fatigue resistant grating

Most importantly, however, our steel metal grating resist fatigue many times better than traditional steel grating since our cross tubes leverage the fatigue in similar fashion as crimped flat bars in riveted grating. Of course, considering same bearing bars dimensions and comparable bearing bar spacing. Please keep in mind that our bearing spacing includes two kind of spacing, distance between the HSTS’s or HSTR’s and internal spacing between the vertical walls of the tube.

Our tubular structure of bearing tubes and cross tubes provides superior resistance to fatigue. The equal percentage of horizontal surfaces to vertical surfaces increases resistance to high amplitude and low frequency vibration.

The square or rectangular shape of bearing tubes with 2:2 or even 3:2 ratio between vertical and horizontal lengths reduces the twisting effect of load carrying elements. For comparison, the bearing tube 2″x 2″ x 0.250 has a leverage of 1:1 but comparable bearing bar 2″ x 1/4 has leverage of 8:1. Therefore it is 8 times easier to twist 2″ x 1/4 bearing bar than 2″x 2″ x 0.250 HSTS bearing tube.

Extremally high bowing resistance

Our steel metal grating’s weldment resist both bowing types, longitudinal and traverse as it is high fatigue and load resistant grating. The cumulative effects of fatigue vibration, high load and inadequate support cause bowing in most traditional steel grating. The effects of rust accumulation also contributes to reduction of resistance to both load and fatigue. That is why excessive rust increases bowing and reduces utilization of grating.

Our bottom bars are rather unique in metal grating. Their development have originated in our improvement phase of steel grating when we were improving steel metal grating produced by others. These bottom bars reduce traverse bow which is so detrimental for concentrated load in areas where wheels touch the grating. The bottom bars complement the high density areas of cross tubes in steel metal grating with depths of above 2″. These bottom bars prohibit traverse bowing by restricting elongation of distance between the bearing tubes.

Weight and drainage of our grating

Our client should consider weight and drainage factors of our grating weldments prior purchase. Our grating weldments’ weight exceeds by about 25% similar traditional grating. It could also become about 40% heavier when we increase the volume of cross tubes in the panel. Therefore we recommend using our lifters during their installation process. They are coming free of charge with your grating weldment’s shipment.

These steel metal grating weldment panels should be lifted by two workers using our lifters. On client’s request, we can reduce the width of a panel to reduce the weight. In fact, we can reduce the width of grating weldment panel to about 2 feet for easier manual handling.

The necessity of manual handling increases number of panels ordered. If you plan to replace 2 damaged panels with widths of 3 feet each, the number of panels will increase. The scenario refers to replacement of one panel damaged by left wheel and the other damaged by right wheel. Since our panels for manual handling can reach up to 2 feet, we can produce two panels of 1.5 feet width for left side and 2 same size panels for right side to fill the gap. Therefore all together we will produce 4 panels instead of 2.

Sacrificing drainage to increase maximum load is a normal strategy in grating business. Manufacturers reduce bearing bar spacing to increase the density of bearing bars and increase the maximum load. The reduction of spacing also reduces the drainage. In our case the cross tubes and bearing tubes bring also reduction of drainage. The bottom cross bars also reduce the drainage a little.

Preventative maintenance monitoring and basic repairs

The preventative maintenance monitoring is very important for any steel metal grating. Such preventative maintenance could involve measuring of bows deflection and preferably repairing of cracks. Finding cracks on traditional steel grating is rather difficult since they are only visible to more experienced workers.

Finding, cracks on our steel metal grating weldment is easy, if any, they are located on large welds joining cross tubes to bearing tubes and broken welds of bottom cross bars. After panel cleaning, apply penetrant then developer and then watch for characteristic bleeding indicating a crack. Once you identify a crack in the weld, remove the weld by grinding and then place new weld there. I would recommend going slightly hotter for better penetration.

When and where to use our steel metal grating weldments?

The purpose of our grating is to increase the useful life of specific panels that are damaged most often. In this way, you do not have to replace all panels in your grating area. As the replacement of damaged panels with the same type of panels and expecting different results lies on the border of insanity, the replacement of damaged panels with our grating weldment panels simply makes sense.

In fact, if according to our calculations one candidate of steel grating is on the border of acceptance for improved production then you can opt for improved grating first. The improved styles are less expensive to produce instead of ordering our steel metal grating weldments. Once our improved steel grating will deteriorate than you will have to decide if it make sense to order our grating weldments.

However, if the best candidate for steel grating meets our requirements in 70%- 80% than we will try to convince you to go with grating weldments. Once our improved steel grating will deteriorate than you will have to decide if it make sense to order our grating weldments.

Contact us to quote

Prior contacting us visit grating steel measurements to become familiar what measurements we require and what additional information you will need to provide prior quoting. With all information easily accessible visit contact us and select quote, and then grating. Next select grating weldments and follow the instructions. Remember, you will need to tell us location of the panels and what drives on them. We have designed our contact page that is comfortable for people without any technical background. The most advanced clients with engineering backgrounds will find useful shortcuts to speed up quoting process.