In our steel grating world the heavily regulated manufactured product meets old infrastructure, abuses of weather, heavy dynamic loads of ever bigger vehicles, and abuses of their drivers. In this world, new infrastructure projects shine with well engineered bridges and roads with properly selected grating. However, on opposite side of the same world, in secondary market, forklift’s wheel goes through hole in rusted grating and the load slides off the forks.

As a mother company of JW Portable Welding & Repairs, we have been involved in repairs and replacement of grating for about 10 years. We have also advised clients on steel grating selection and we have implemented improvements to existing steel grating. Now, we begin to offer custom and improved steel grating, grating weldments and drain covers that will fit your needs and provide long utilization time. If you require more insight into area of grating and how it is used please click here.

All our products resist better the dynamic loads of multidirectional vehicular traffic. Therefore they offer a grater return on investment into operation of your business. Simply put, they last longer and you do not have to replace them too often. More importantly, they require less repairs.

On this page, I would like to introduce to you not only to classification of steel grating for vehicular traffic but also guide you in grating selection if you want to replace some of the damaged panels. I will also mention some of our grating improvement methods to increase grating’s utilization period.

Contact us to quote

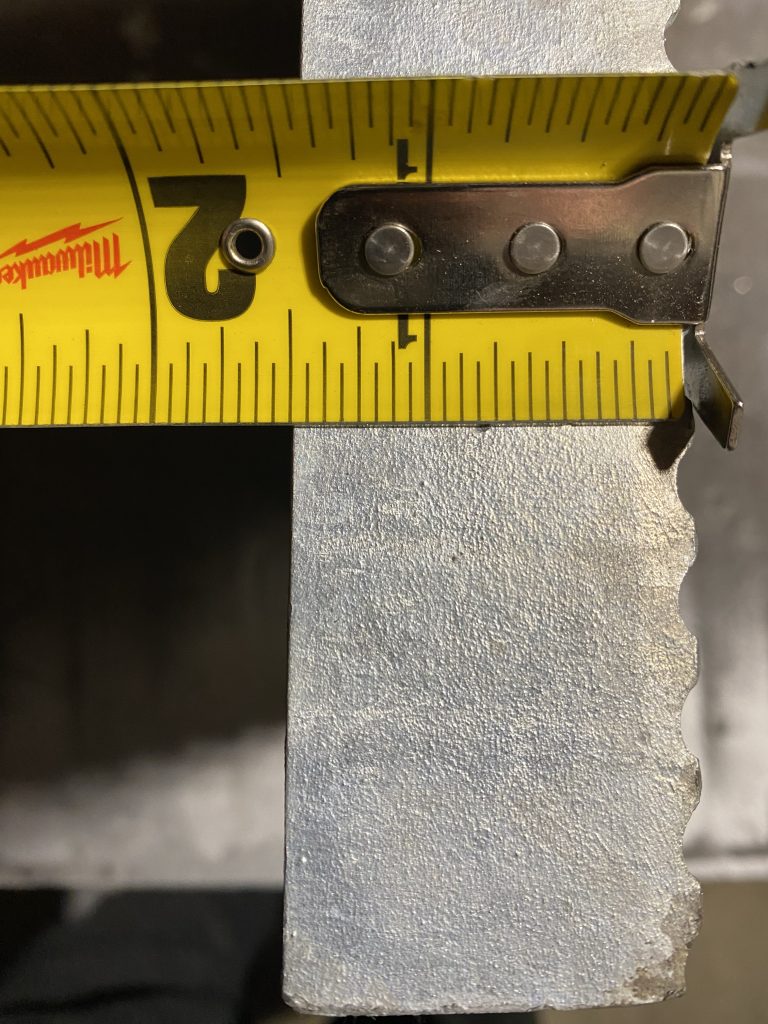

Since we cater to ordinary managers with small and medium size projects in secondary market, we make grating’s selection process easy. We simplify concepts, provide sketches, and guide you in every step. With us on your side, you do not have to be structural engineer to get the right steel grating. You just need to know how to read the tape measure. Even if you do not, we will provide you with images that will teach you how to do it. That is why please visit grating steel measurement prior contacting us for a quote. You will learn there what kind of information we require from you and how to obtain this information.

Then with your new set of information please visit our contact page and simply follow the questions. Our contact page will guide you step by step in the whole process. The contact page allows the both, a novice buyer and a well seasoned engineer experience comfortable step by step guidance as they take separate paths. Once we receive your information, we will check it for merit, possible mistakes and provide you with a quote. If we will have questions, one of us will call you.

In case if you are a structural engineer looking for good quality steel grating, you can select different path on our contact page that caters to engineers. The path designed for engineers is much shorter and doesn’t take as much time as the path for novice. Once we receive your information, we will still check it for merit and possible improvements prior providing the quote.

Now let’s talk about replacement of grating, you can always come back to the contact us page. Let’s learn a few important details prior engaging in quoting and buying process.

Replacement of steel grating

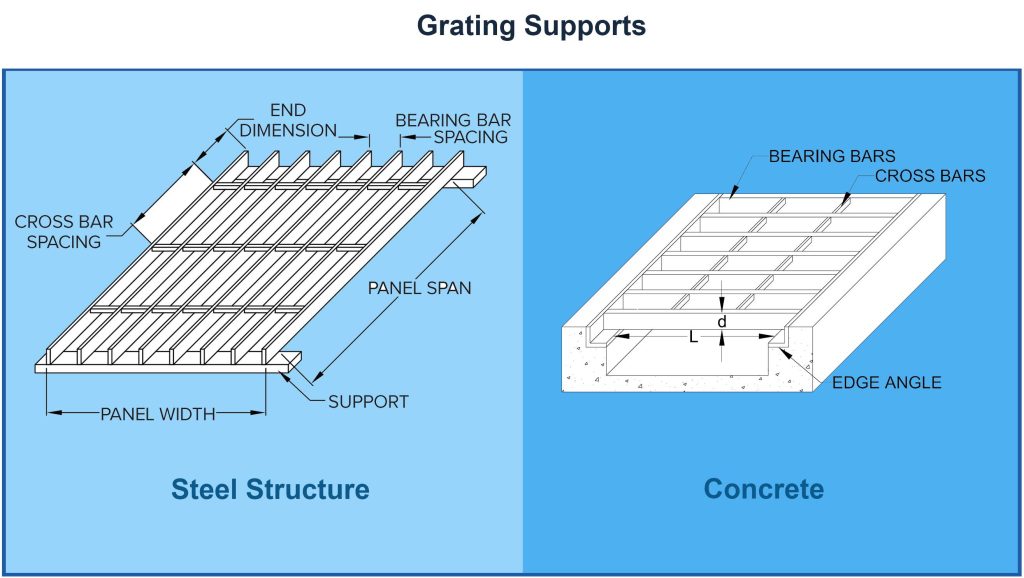

Realizing certain rules, facts, and terminology will help you to make a conscious decisions in replacement of grating for vehicular traffic. Please now open the bar grating concepts and keep it open when you will read about steel grating. You can use “Bar grating concepts” as quick reference to terminology and reference to location of structural elements. Gaining some grating knowledge will allow you also to develop proper strategy for grating’s maintenance and its repairs.

Grating support structure

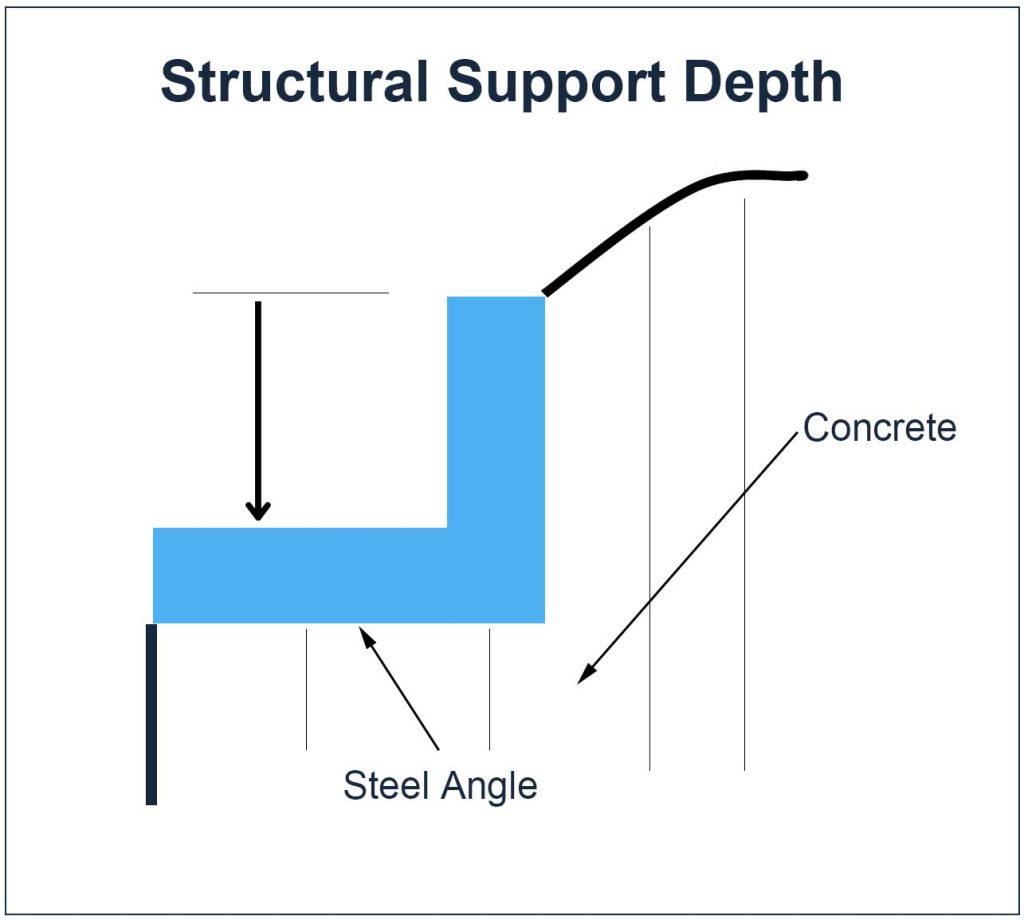

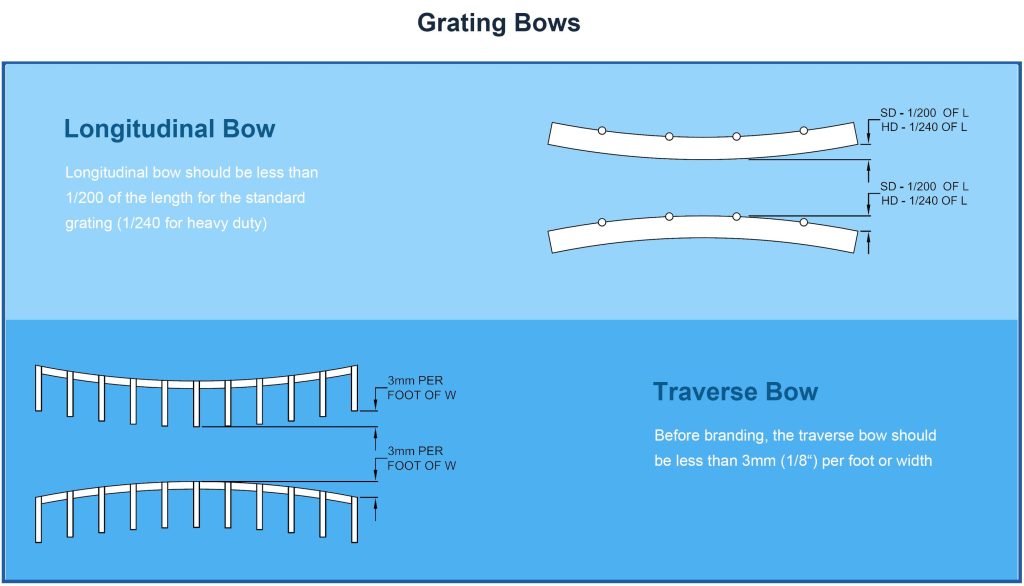

Grating support structure plays tremendous role in extending utilization time of your grading. This support structure in concrete consist of steel angles and on the ramps it consists of the whole ramp’s structure. Unlevel support, rusted support, and lack of grating support will significantly shorten the life span of the grating. The excessive longitudinal bowing and traverse bowing and than cracks development will deteriorate your grating sooner.

The best quality steel grating will fail prematurely if you your support structure is substandard with multiple problems. In order to invest in good grating you must repair its foundation which is its support structure. If you are looking for a contractor to do it, we will gladly take care of this task for you if you are located within 150km radius from London, Ontario.

Many times we have noticed welds on grating support structures with large weld caps. Most maintenance managers do not pay any attention to them. However, these weld caps cause initial rocking of grating panel along banding bars. Then they cause longitudinal bowing of the whole panel. Repositioning the bent panel to another place and placement of a new panel to the same spot also does not work. The excessive cap will soon damage the new panel. Therefore, we usually grind off the excessive welding caps flush.

Exposed concrete instead of steel angles does not provide proper support for heavy dynamic loads and vibration. Vibrating grating panels under heavy load will cause concrete cracks under banding and where significant longitudinal bows are located.

Fortunately, we provide mobile service that can repair the old angular support in concrete by replacing old sections of angles with new angles.

Depth of bearing bar in old steel grating

The depth of bearing bar is a crucial factor in replacement of steel grating. Measuring existing bearing bar depth is a first step in steel grating replacement. In concrete trenches it is the vertical distance between top of the angle toe and the bottom tow on the root side. In case when the concrete is bulging close to the angle and the old grating has excessive bowing than we can increase the depth of bearing bars by the bulge of the concrete.

The increase of depth of bearing bar will increase the maximum load of the bearing bar. It will also increase the maximum load of the whole panel. However, going beyond the described above bearing bar depth will cause bending of bearing bars. It could prone them even to collapse.

Simply put, the depth of bearing bar is the thickness of the grating panel.

Depth of bearing bar can not be increase unless you will change all panels

The depth of a bearing bar on the ramp is the distance between the bottom of the bearing bar and it’s top and all steel grating panels have the same depth. For simplicity, the bearing bar depth is the thickness of grating panel. Unfortunately, we cannot increase the depth of bearing bars on ramps for new panels without certain improvements since the wheels of forklifts will start bending them. These improvements can only increase the depth by 1/4″ to 1/2″ and only on horizontal sections.

The most popular dimensions for bearing bar are 1 1/2, and 2″ although you can purchase also 1″, 1 1/4, 1 3/4, 2 1/4, 2 1/2, 2 3/4 , 3, 3 1/2, 4″ and so on.

Thickness of bearing bar

Measuring thickness of the bearing bar is the next step . Most manufacturers produce steel grating’s bearing bars for vehicular traffic in thicknesses at least 1/4″. In fact 1/4″ is the most popular bearing bar thickness in our secondary market. Bearing bars with depths of at least 5″ could have thicknesses of 3/8″ or even 1/2″.

If your existing bearing bars are 3/16″ thick than they are most likely not suitable for heavy vehicular traffic. The bearing bar thickness of 3/16″ suits panels for mixed pedestrian and vehicular traffic. However, if your old grating is in good shape with no rust and no bowing than we can improve it to sustain heavier loads. These improvements consists of much heavier banding, anti-vibration welds and bottom cross bars as well as many other. You can also consider modification of existing grating to locations with smaller traffic and ordering more suitable steel grating for vehicular traffic

Bearing bar spacing in old steel grating

Measuring old grating’s bar spacing is the third step. Bearing bar spacing is the distance between centers of two closest parallel bearing bars. The bigger the bar spacing than the panel contains less bearing bars and it can not accept as heavy loads as panel with smaller distances between the bearing bars. The bearing bar distance is measured in 1/16s. Therefore, number 19 means 19/16 which is 1 3/16″

Grating with with smaller spacing than 19 such as 13 and 15 are called mesh grating. Mesh type bar grating with same size of bearing bars can sustain larger loads due to denser position of bearing bars. Grating with larger gaps (bar spacing) such as 30, 38, 44 are called wide gap and extra wide gap.

If your old steel grating shows large bowing we strongly recommend mesh type of bar grating while maintaining bearing bar sizes. Additionally, we would try to get not only mesh grating but also steel grating with thicker bar sizes. You could also try some improvements involving additional support in the middle with the objective to reducing the span. Moreover, there are custom improved grading that increase maximum load and impact, grating weldments with even stronger resistance. And, then there are trench and drain covers made from compound grating.

Cross bars and cross bar spacing

Measuring cross bar spacing of the old grating is the next step. Cross bars are elements of steel bar panel that are going perpendicular to bearing bars. These elements are not responsible for caring the load but for maintaining the structural integrity of the steel grading. Most of your existing panels cross bars are in form of the round rods or twisted rods. These steel panels with rods are standard steel grading with lower structural integrity. They are well suited for pedestrian traffic or combination of light vehicular traffic and pedestrian traffic.

Steel grating for passenger traffic does not resist dynamic load and impact as good as grating suitable for vehicular traffic. The grating for vehicular traffic has a heavy duty (HD) symbol and it contains steel flat bars as cross bars connecting load bearing bars. The depth of these cross bars tends to increase along the depth of increased bearing bars reducing leveraging moment acting on steel bars for vehicular traffic.

It is worth mentioning that some manufacturers can produce same grating with double the number of cross bars in the attempt to improve structural integrity of their grating. Such grating contains usually letter F in their code.

Wrong grating

If you have old steel grating for passenger traffic where suppose to be heavy duty grating for vehicular traffic and this grating is showing early signs of bowing but does not have rust than we can increase the loading capacity of this grading and/or reduce significantly traverse bows.

In initial stages of panel degradation contact us and click repair then follow the instructions. Once we receive your information, we will instruct you what to do. Some repairs can be done on site but we do majority of heavy repairs in our shop.

If you are located within our servicing area we will try to perform these repairs on site. However, if you are located outside of our servicing area or your grating requires heavy repairs than you will need to ship these grating panels to us.

Span of steel grating

The span of steel grating determines the length of grating panels. Since you want to minimize the span as much as possible in order to increase the possible load tolerated by grating panel, therefore the span of grating panels goes along the width of the trench and it is measured inside the opposing still angles.

We calculate number of panels needed by dividing the length of the trench by width of the panel in your type of steel grating. The partial width panels will fill the rest of empty space.

As simple as span concept is we have visited many places where support for span was not existing or substandard. Occasionally we have seen span too long for particular grating even for occasional traffic.

Maximum clear span between supports

It is an excellent idea to compare the measured span with allowable span for your grating in your particular traffic category. Each manufacturer will provide maximum clear span between supports for specific steel grating in particular traffic. In my opinion, we should oscillate within 60% to 75% of maximum clear span recommended. In this way, you could accommodate heavier vehicles than expected without damaging your steel grating panels.

Distance between panels

Distance between the panels and the steel angles that provide the support should be about 3/16 to 1/4 if you regularly must clean these panels and the trench. The dirt accumulates in this gap and smaller gaps are more difficult to clean up prior removal of panels. Additionally, rust accumulates there too making removal of the panels very difficult.

We have witnessed many times steel grating being damaged during the removal since the rust pressure locked the grating panel up.

That is why most of our panels are hot deep galvanized to avoid rust accumulation. We especially recommend hot deep galvanization for panels that are frequently removed.

Distance between the panels should also be at least 1/4″. Although, many maintenance workers prefer gaps of 1/2″ for easy panel removal. The maximum panels gap between frequently removed panels should not be bigger than bearing bar spacing. And, only if these panels do not move under the movement of vehicles. The moving panels can increase the gap between some of the panels and cause premature deterioration.

Banding

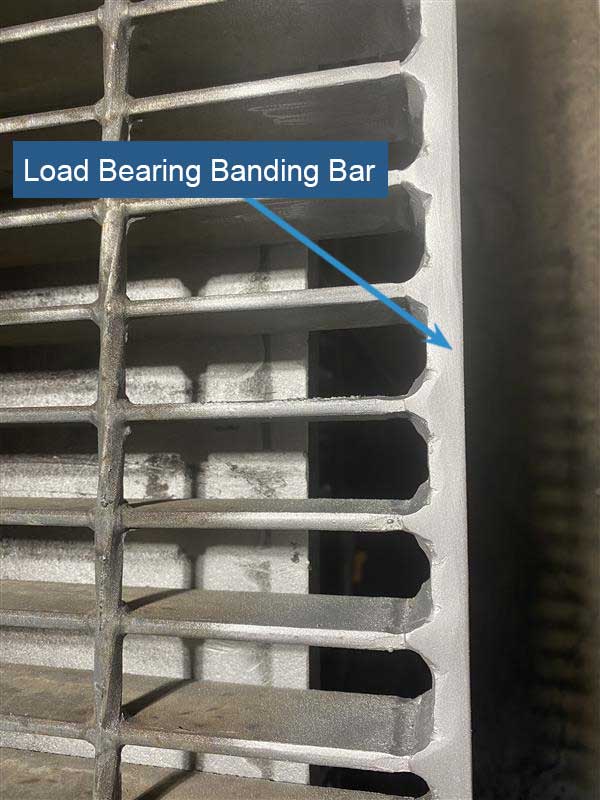

Banding plays a significant role in the strength of steel grating panel. The banding flat bar is position perpendicularly to all bearing load bars. Each panel contains 2 banding bars, and I would argue that these 2 flat bars play the most significant role in maintaining the whole panel’s structure intact, if the panel is wider than longer which is often the case in trenches.

The traverse bowing of the bearing bars under excessive loads twists the banding. The traverse bowing of grating panel that is directly associated with impact of vehicular movement affects precise locations of the bearing bars bows.

As the damage progresses, the bearing bars’ bows increase and they transfer the bow to banding bar. In narrow the trenches, the bearing bars are shorter and they transfer the bow quicker to banding bars. That is why the strength of banding bar is very important. Please note that very narrow trenches under severe multidirectional dynamic load of vehicular traffic require trench or drain cover structure of compound grating rather than traditional steel grating.

Our banding improves steel grading resistance to bowing

That is why we focus our efforts to improve banding strength as much as possible. First, we use banding that is much thicker than thickness of the loading bar. For 1/4″ thick loading bars we use 3/8″, 7/16, or 1/2″ thick loading banding. Additionally, for 3/16″ grating for pedestrians or for light vehicular traffic we use 3/8″ banding. That is why our customized steel grating panels do not bend so often. In order to find out more about our improvements please click improvements.

We have also experimented with H&Q steel banding, but the results were not as positive as expected due to overheating. Then we have used different welding technology to significantly reduce heat but the results were also not satisfactory due to lack of proper penetration. Presently, we experiment with steel composite structure elements for banding.

Anti – vibration welds

Our anti-vibration welds play tremendous role in resistance of impact and vibration caused by vehicular movement. If your grating panels are damaged with unattached and twisted loading bars that have broken off from banding than you have excessive impact and/or dynamic load problem.

At beginning, you notice only one unattached loading bar that broke off from banding, but what you do not see is cracks in welds of the surrounding bearing bars. Soon you find 3 or 4 loading bars unattached from banding in the same spot. Next, you hear is scream of a driver whose vehicle has one wheel in a hole in your grating.

Manufacturing progress

Many manufacturers are well aware of this issue and they have responded in form of dense mesh grating. This approach allows not only to spread the load on grater number of bearing bars but also allows high heels traffic. More importantly, from our perspective this dense mesh grating spreads the vibration on greater number of bearing bars, and therefore it reduces the vibration amplitudes acting on singular bearing bar. So, now you can purchase pressure locked grating with distance between loading bars of 13/16, 11/16, 9.5/16, 8/16 or even 6.5/16. Wow this is a real technological achievement. And, and this grating is available from 3/4″ depth.

These dense mesh grating steel looks impressive too, but try to lift it and you will need a forklift to do it. If you need to clean your trench a few times a year and you must remove grating panels 3 or 4 times a year then you have to ask yourself if you want to remove and then install grating panels with a forklift. Additionally, you should consider excitement related to cleaning of this dense mesh grating. Believe me, you will experience plenty of it. The dense mesh steel grating have significantly reduced drainage. Therefore, dirt and debris tend to accumulate on top of panels.

As you can see there is no magic wand in steel grating.

Our customized steel grating has anti – vibration welds

All manufactures produce steel grading according to ANSI/NAAMM standards and these standards require welding of bearing bar to banding on one side of loading bar. And, this is not anti – vibration weld. The North American and Asian manufacturers produce grating panels that resist impact but high amplitude and low frequency vibration is not an impact. This is a dynamic load.

All our custom steel grating panels have anti-vibration welds and you can place them in spots of your trench, pit or ramp where the structure is exposed to intense vibration. Therefore, you do not have to replace all of old panels but only replace panels damaged by dynamic load and keep the rest of old panels. This is the power of customization.

Riveted Grating

Riveted grating is the most reliable grating for heavy vehicular traffic. This type of grating uses technological concepts developed centuries ago but still useful today in most rugged industrial applications. Riveted grating is preferred by engineers for many applications since it provides higher maximum loads for span and for the same dimensions of bearing bar. This type of grating provides superior resistance to buckling caused by vehicle movement. Therefore you will never see twisted bearing bars in riveted grating. The riveted grating proves to be superior from all grating types for dynamic load.

However, this type of steel grating is not as popular as it used to be. We haven’t seen it often in our maintenance projects in secondary market except in old industrial complexes and in high priority ramps or docks. I have also noticed this type of grating in old bridges in Canada and in US as well as bridges in Europe. Riveted grating provides comfortable walking conditions and movement of casters due to trapezoidal shape of reticulated bars. The rivets at higher points of reticulated bars keep the whole structure durable. Such assembly makes the whole structure resistance to stress and joint failures. It is worth noting that these reticulated bars can be serrated that will improve safety.

It is worth mentioning that our grating weldments initial designs were based on minimizing effects of force leverage used in riveted grating.

Riveted steel grating in secondary projects

Perhaps one of the reason for lack of grater popularity is a higher cost of riveted grating in comparison to traditional heavy duty grating. Another would be still comparable maximum loads of heavy duty grating and riveted grating for similar bearing bar sizes. To clarify, riveted grating provides higher spans for the same size of bearing bars but this advantage is minimized by a higher cost …..and long waiting time to get it. Also, static loads for comparable grating in both categories in smaller depths of bearing bars are similar.

Additionally, customization of riveted grating is much more difficult. Most of manufacturers provide customization of riveted grating in timely manner which means you will have to wait long, long time. In many maintenance projects related to steel grating, clients simply do not have the luxury of long waiting time. Clients simply must load and ship their products, and technicians must repair or clean cars and trucks. Business cannot wait to make a dollar.

In my opinion, there is no doubt that riveted grating provides grater utilization time in comparison to heavy duty grating and guarantees a superior safety factor. That is why it is used for first priority infrastructure projects. However, until we decide to build third priority structures that suppose to last hundreds of years than up to this moment unfortunately riveted grating will stay in the shadows in secondary markets.

Welded vs Pressure Locked Steel Grating for Vehicular Traffic in Secondary Market.

We all agree that riveted steel grading takes priority in infrastructure projects. However, most property owners and maintenance managers do not deal with first priority infrastructure. They form secondary market for steel grating and in this market there are basically two kinds of grating, welded steel grating and pressure locked steel grating. The question I have been ask so often is “What kind of grating should I use for the trench in my shop?”. So, what kind of steel grading would I recommend for vehicular traffic in secondary market?

In the secondary market for vehicular traffic versatility, strength and load capacity, durability and flexibility of shape are the most important.

Versatility factor

Welded streel grating is available in wide range of configurations, bars spacing, and bar depths. This versatility makes it the most popular in various industrial and commercial projects.

Pressure locked grating has also great variety of choices but definitely it has fewer options.

Strength & Load Capacity

Welded steel grating offers excellent strength and load capacity. More importantly, it is suitable for heavy – duty applications where higher load capacity is required.

Pressure locked grating is usually not as strong and is more suitable for for applications with lighter loads.

Durability

Welded steel grating is very durable and it is highly resistant to wear and tear. It can resist harsh environments and it has excellent utilization time. Moreover, welded grating characteristics can be improved using variety of methods already mentioned on this page.

Pressure locked steel grating is also durable but not as durable as welded grating. Therefore, pressure locked grating excels in less durable environments.

Flexibility of shape

In secondary market of vehicular traffic flexibility of shape is extremally important. Lets not forget that in this market significant number of panels have longer widths than lengths. Moreover, if the lengths of panels are bigger than widths, they are bigger not by much. Therefore, these rectangular panels are looking squarish from the first look.

When the width of a panel starts playing more important role in overall strength of the panel then the importance of load bearing banding becomes more crucial. That is why we provide anti – vibration welds on steel grading. Since the banding is welded to the steel panel disregarding how the panel is made therefore the slight advantage of lower cost of pressure locked grating is minimized and welded steel grating is preferable.

Conclusion

In conclusion, both welded steel grating and pressure-locked steel grating have their own unique features and applications. Welded steel grating offers superior durability, strength and load capacity, and flexibility of shape. Therefore, I strongly suggest welded steel grating for vehicular traffic in secondary markets. Additionally, I think pressure locked steel grating is more preferred for pedestrian market.