Bar grating can become challenging very quickly especially if it is destine for Vehicular traffic facing extreme loads and impacts. Reading text about these challenges for a novice could become also very challenging due to strange and perhaps confusing terminology and presentation of complex engineering problems. We attempt to simplify challenges and make technical reading comprehension more comfortable for visitors therefore we present to you “Bar Grating Basic Concepts”. Keep this page open when reading our pages for quick technical references. The vehicular traffic grating follows exactly these basic concepts. Additionally, please keep it open when reading about our improved grating or custom weldments for vehicular traffic such as trench covers, drain covers, driveways, and pit covers.

The Bar Grating Basic Concepts does not cover other types of grating, For more insight regarding other types of grating please click here.

We also realize that this page will be frequently updated and revise to follow our visitors comments and to provide technological updates. We also plan to follow the common knowledge summarized in proverb as “variety of ways to skin the cat”. Therefore we will update this page for these “variety of ways”

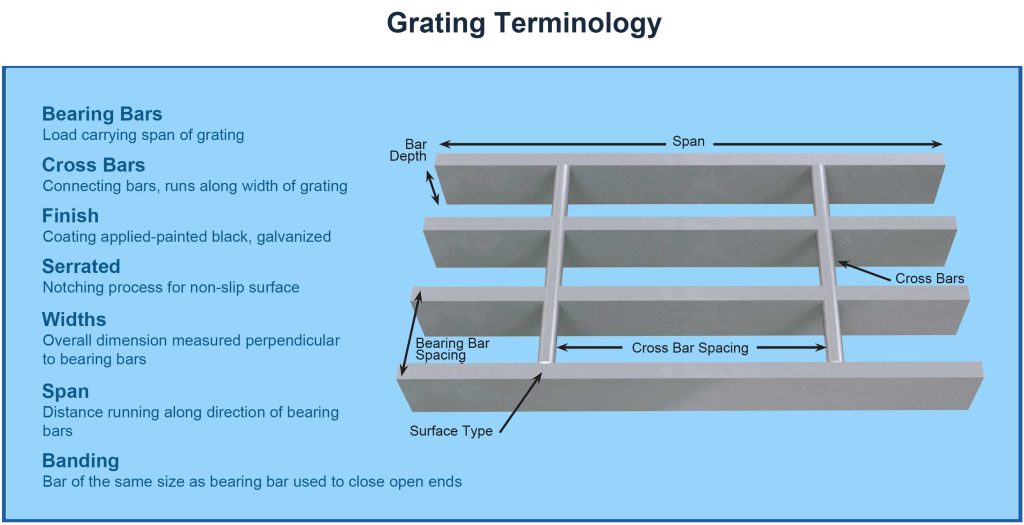

Bar grating terminology

Here is a basic version of bar grating terminology

Please notice that following sketch does not show you where the banding bars are although it describes them. It also does not tell you where is thickness of bearing bars, although it tells you where bar depth is.

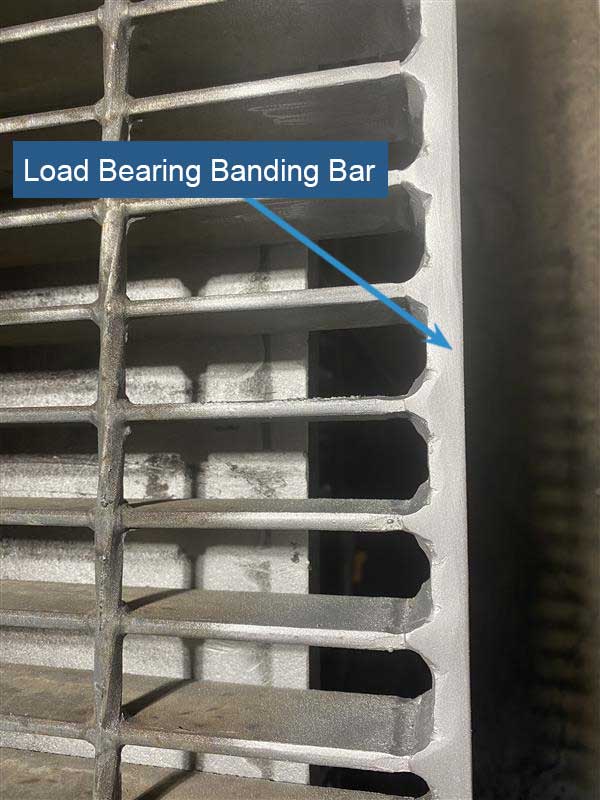

The banding bar closes open ends of bearing bars on both sides of the panel. However, this banding bar is not necessary in the same size as bearing bars.

The load bearing banding bar carries the load, but other banding bars can improve drainage. The drainage improvement of banding bars happens when drainage is more important than load carrying. Therefore in high water areas under low loads the banding bars could be positioned differently.

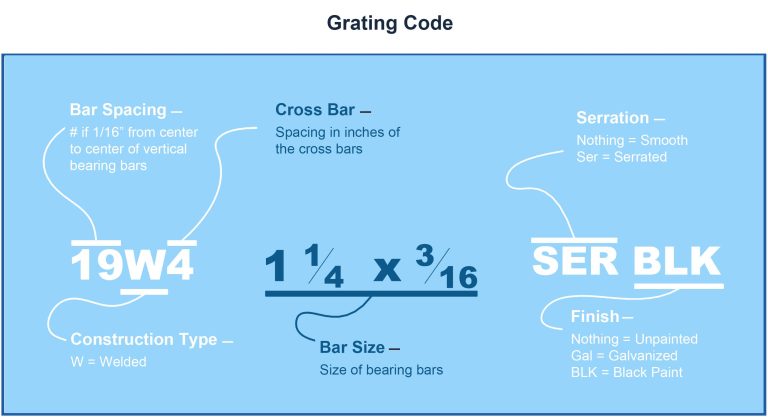

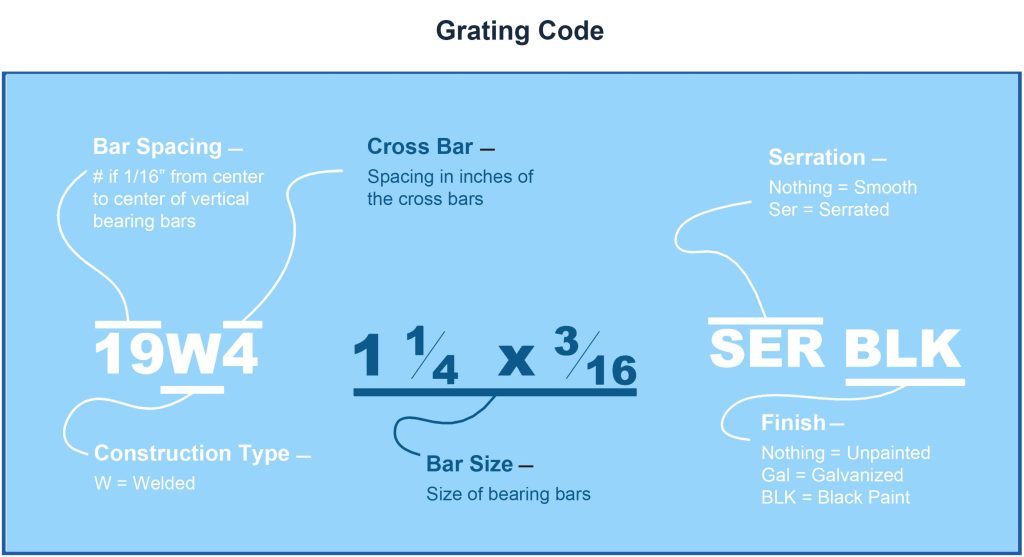

Bar grating code

The bar grating code is a basic description of bar grating in form of code.

The presented above bar grating code shows the way how manufacturers recognize themselves what kind of bar grating they are producing. However, this code is only useful for basic type of bar grating since only basic type of bar grating is readable by clients who purchase bar grating.

Due to significant technological progress of bar grating and manufacturers’ attempt to increase their marketing advantage the bar grating code can get very complex.

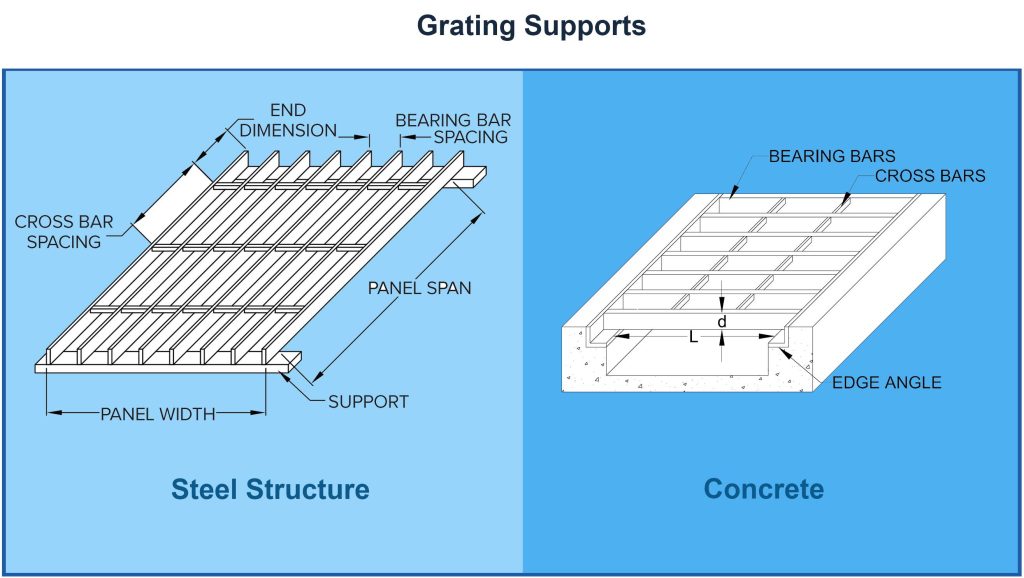

Span based on bar grating support structure

There are 2 golden rules in span bar grating

- The span of the bar grating panel runs between the shortest supports.

- Therefore the span of bar grating panels run along the width of the trench and the width of panels run along the length of the trench

- The vehicular traffic direction should always be perpendicular to the span’s direction of bar grating. Therefore the vehicular traffic should run perpendicular to bearing bars.

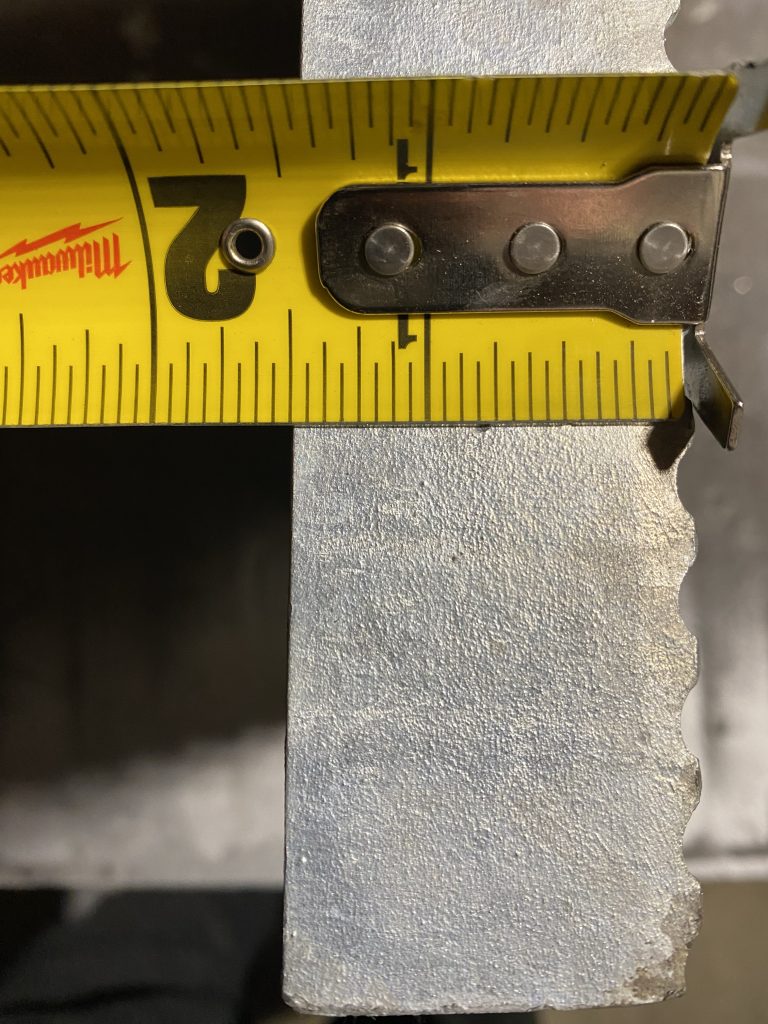

2 ways to measure bearing bar depth

The bearing bar depth is the crucial factor in determining what kind of grating you want. Simply put, the bearing bar depth is a grating bar thickness. This statement is not exactly correct but it simplifies for many customers how they see the panel. Obviously, the thicker panels can carry larger loads than thinner panels. However, there are also 2 main factors to increase the load carrying characteristic of the panel aside of panel’s thickness and they are: bearing bar thickness and bearing bar spacing.

You simply measure your old grating’s bearing bar depth.

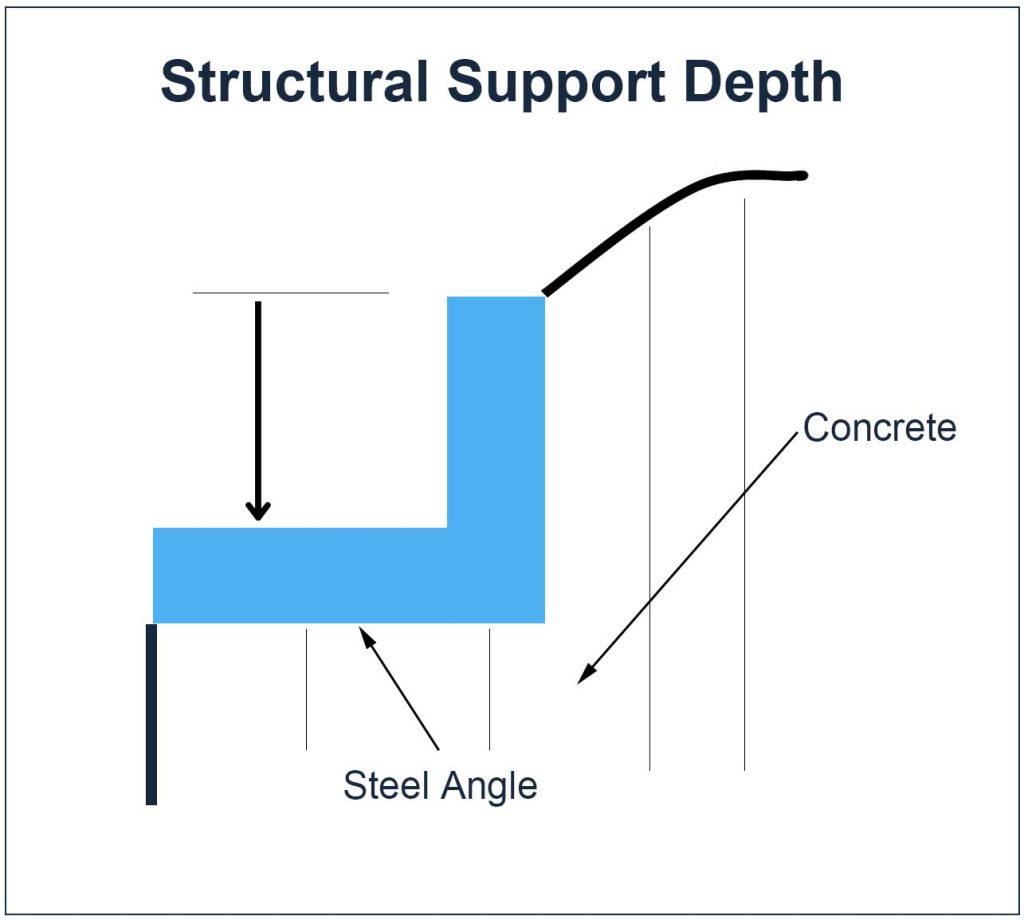

You can also measure structural support depth of your trench.

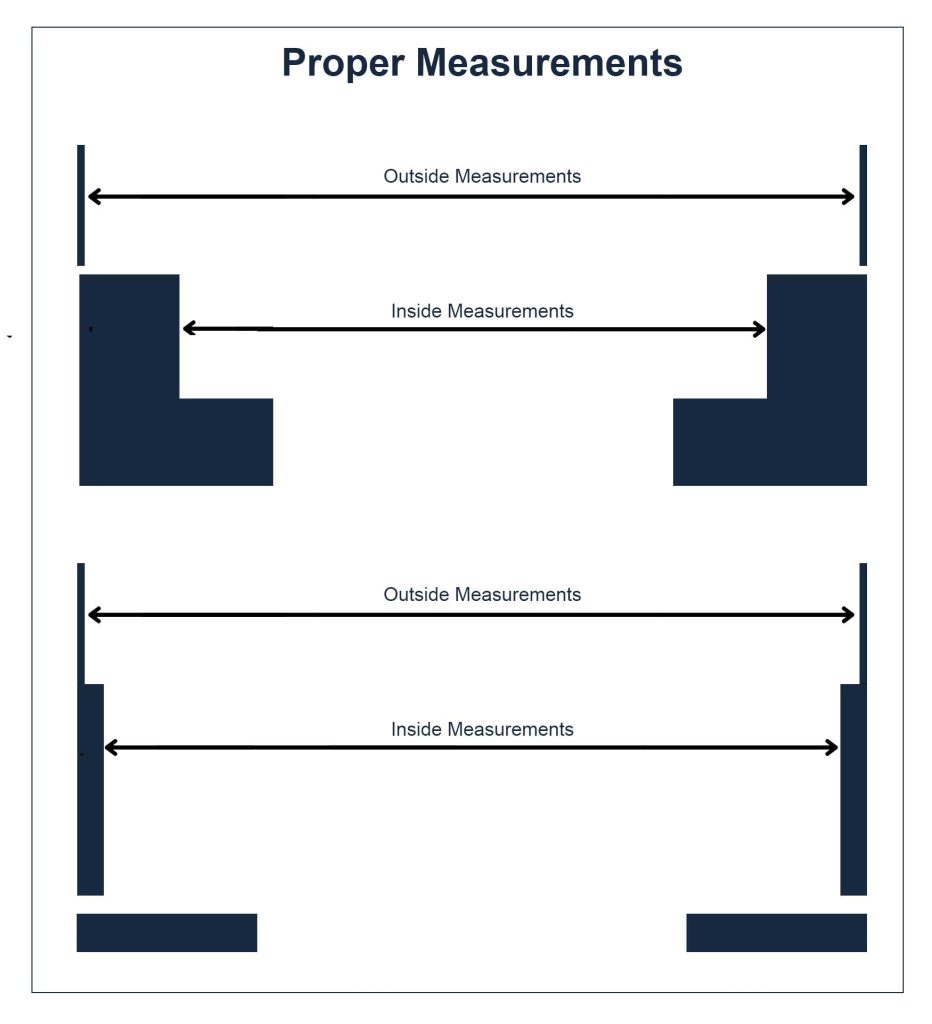

Inside measurement for new grating

Manufacturers want you to provide the dimensions of grating area. These dimensions include grating area’s length and grating area’s width. In case of trench these dimensions are inside measurements. Here is the way how to take these measurements.

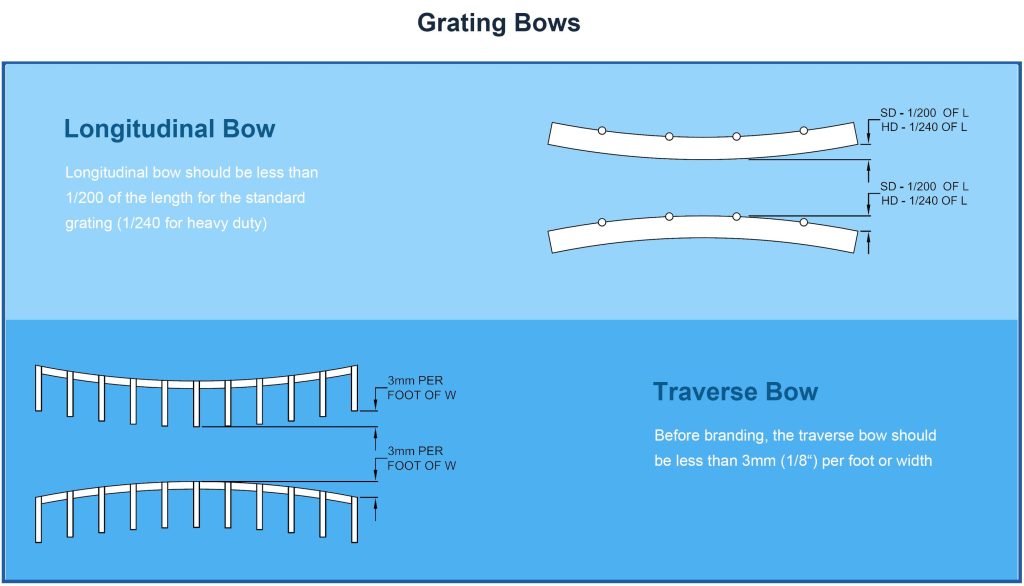

Excessive bowing

Excessive bowing is a sign of panel degradation. We have developed the table of bowing deflections within our preventative maintenance programs to monitor degradation of panels. Other signs of degradation include:

- cracks of cross bars,

- crack of welds between cross bars and bearing bars

- missing sections of cross bars

- leaning bearing bars

- twisted bearing bars

- broken bearing bars

- leaning banding bars

- missing sections of banding bars

- holes in a panel

Here are 2 types of bows.