Here you will find the the description of grating steel measurements that we need to provide the quote for you. This page does not cover measurements for other types of grating. We suggest to follow these measurement procedures since the accurate measurements and their readings are necessary for your new grating to fit its support. The explanations contained on this page will become very handy when filling out information on our contact us page. Additionally, please refer to Bar Grating Basic Concepts for a quick refreshment of grating steel concepts.

For more in depth explanation of concepts and issues related to replacement of grating steel for vehicular traffic click here. You will find also more insight of drain covers as they usually face too heavy loads for the thickness of the panel. And, for more in depth explanation of concepts and issues related to replacement of grating steel for pedestrian traffic click here.

Our explanation of grating steel measurements follows the NAAMM recommendations in simplified form to guide a novice buyer of grate steel in steel grating replacement process. Our guidance contained in this page will explain to you what kind of information you need to provide to receive a quote from us or any other supplier of grating steel. However, when you will face the need for custom weldment grating due to high loads, longer span or most popular shallow depth, than we will have to ask more questions. We also instruct you how and where to conduct proper measurements in order for us to quote on them.

Metalgrating.ca requires following prior quoting

We need to know following information

- Location of your steel grating

- Type of vehicles entering the grating area

- Exitance or lack of angle support

- Bearing bar depth in inches or centimeters for each grating area

- Inside distances of length and width for each gating area in inches or cm

- Length and width in inches or cm of each panel along with its span for each grating area quoted

- Serrated or Non Serrated and Unpainted or Galvanized. We recommend hot galvanization.

- Indicate need for custom improvements. I your grating steel panels last maximum 3-4 years than we recommend improvements

- Old grating steel’s bearing bar thickness and depth

- Images of your old steel grating areas and their panels. We need images of all most damaged grating panels taken from front and back.

- Sketches of grating panels arrangement within each area for more complicated area’s shapes only.

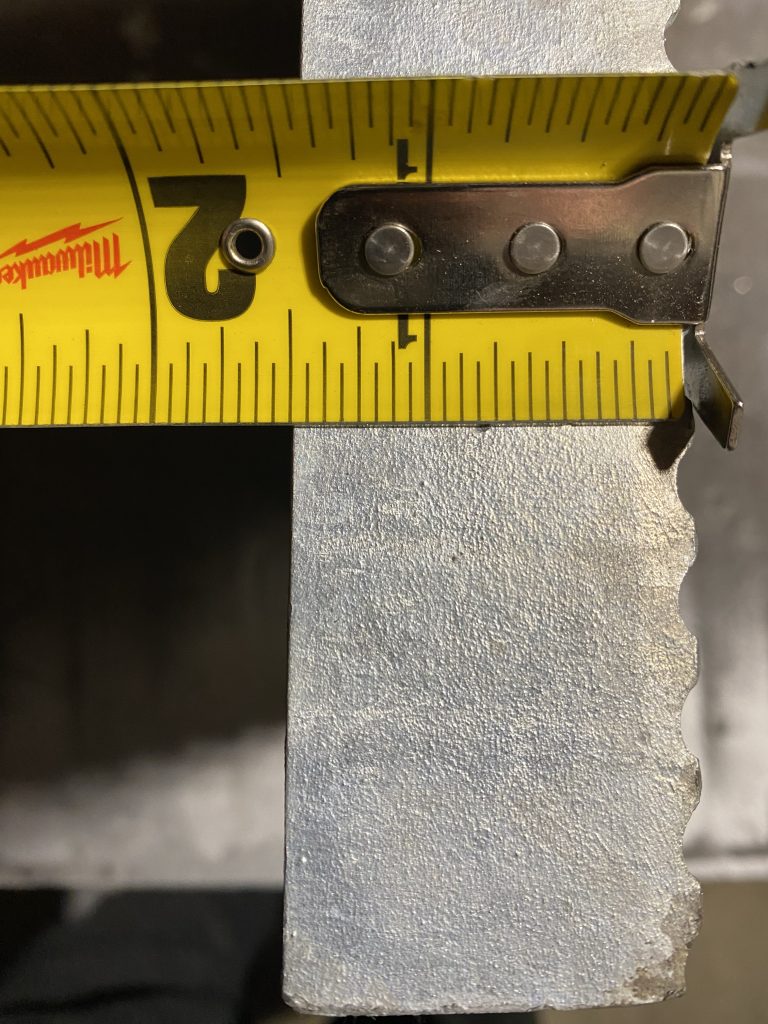

Measuring with a tape measure

As the old generation of Canadians was used to measuring with tape measure, the younger generation is less familiar with precise measuring with a tape measure. Lets start than from basics regarding good tape measure characteristics, inside and outside measurements, measurements in imperial system and metric system, and writing of these measurements. These basic skills will suit you for all your life since you will be able to measure accurately the length of distances and communicate the results properly.

Good quality tape measure

All measurements to replace your damaged grating steel are done with a good quality tape measure. We highly recommend a good quality tape measure that is at least 25′ long and at least 1 inch wide, or at least 8 meters long and 2.5 cm wide. The wide measuring tape is much stiffer than more narrow tape measures and provides more accurate measurements over some open space distances.

If you have a good quality tape measure, please check if hook or tab is at 90 degrees angle and if it is loose. The hook should be loose to accommodate the thickness of the hook for outside and inside measurements and still provide correct measurements. If your hook is bent or out of shape you can straight it out on a thick still plate by tapping gently on the hook.

Good tape measures have bowing tape or blade for longer extension over longer distance without breaking. However, this bowing increases the distance between the material measured surface and the edge of the tape. Therefore, for grater measurement’s accuracy, the good measuring practice is to close the gap between the edge of the tape and the surface of measured material by twisting the tape a little.

With a good tape measure in hand you can approach the measurements with better precision and accuracy.

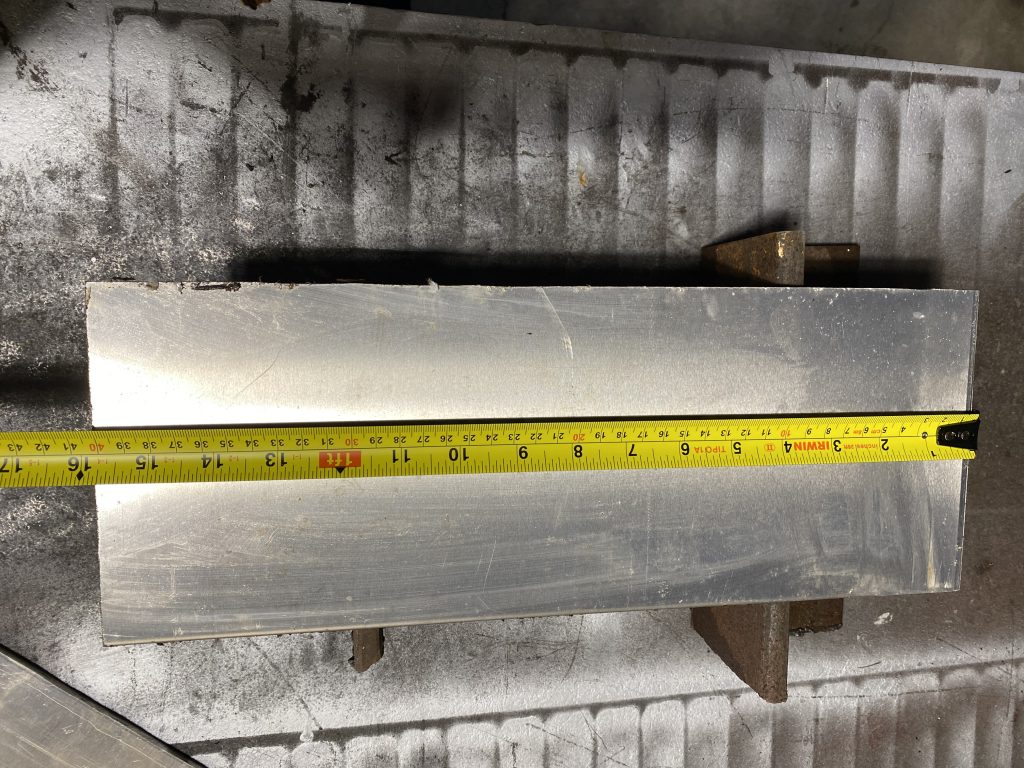

Simple measurement of the length of material

The measurements of material usually involves the measures of material length that is distance from one edge to another edge. Basically, this type of measurement measures the distance between two outside edges of material.

Please note that reading provided in the image above are not yet accurate since the bowing tape creates the gap between surface of material and the tape edges. Additionally, position of our eyes is not perpendicular to the edge of material being measured.

By pressing down on one edge and then another edge I have received more accurate reading on the tape. My readings are 15 inches and 13/16 of an inch or 40 cm and 2 mm. And this is how you should read and communicate verbally these readings.

Please note that 15.8125 of an inch is 40.16375 cm. Therefore, we know that accuracy is sufficient for this tape measurement.

Writing the tape measurements in metric and imperial standards

Obviously, verbal communication is important but written communication is even more important since it is placed on drawings and sketches that support the communication between engineers and tradesmen and, obviously, between us and our clients.

The reading 15 inches and 13/16 of an inch could be written in following ways

- 15 13/16″

- 15.8125″

- 1′- 3″ 13/16″ or 1′ – 3 13/16″

- 1′ 3″ 13/16″

When you will be filling out our contact us page for your quote please use 15 13/16″ or 15.8125″way to write the imperial measurements. The measured lengths are not very long and we simplify our reading therefore we use inches for imperial measurements.

The reading of 40cm and 2mm could be written in following ways

- 40.2 cm

- 402 mm

- 0.402 m

- 4.02 dm

When you will be filling out our contact page for your quote please use 40.2 cm as the metric standard of your measurements. Centimeters are very comfortable for our rather small distances and millimeters are too confusing only very small distances are measured in millimeters.

The millimeters are even more confusing for larger distances such as 15 meters, 40 centimeters and 2 mm. This would be 15402 mm and finding this number on a tape measure would be difficult. However if I will write it 15,40.2 then everything before comma, are meters, the number between comma and dot are centimeters. And, the number after the dot are millimeters.

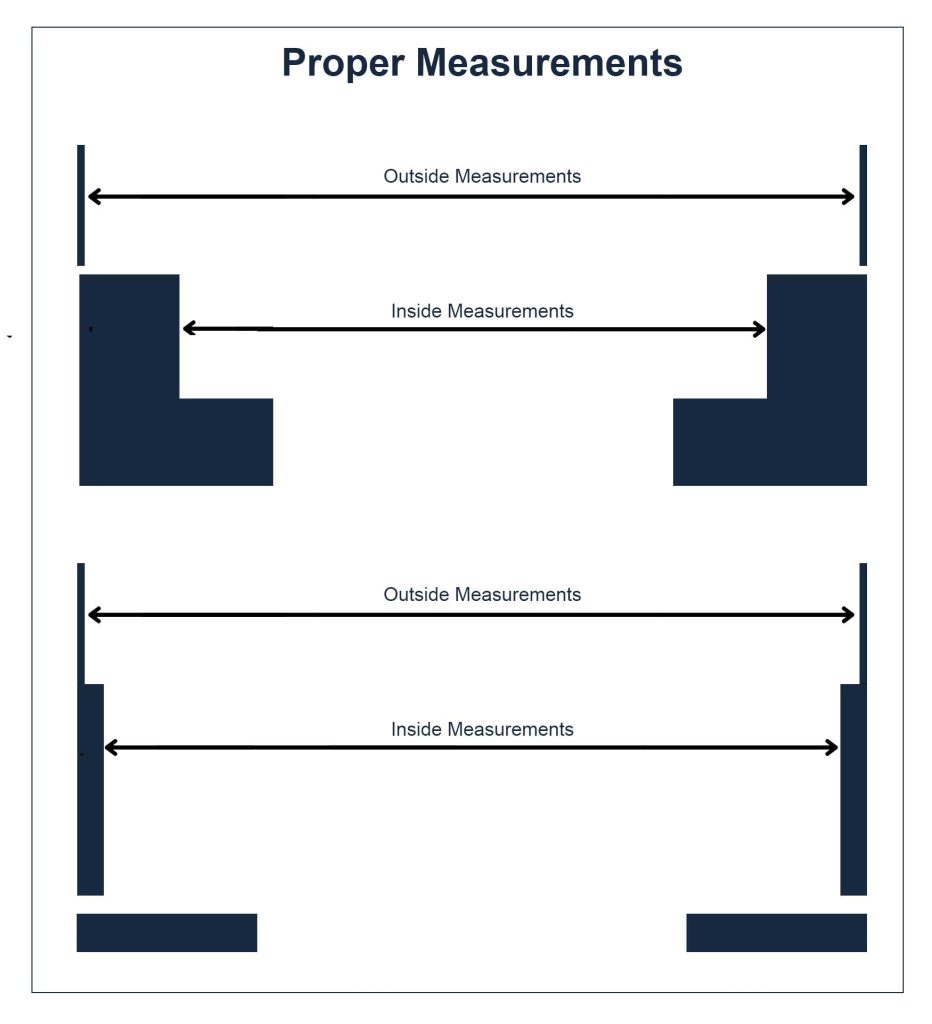

Inside measurements and outside measurements for grate steel area

The difference between the outside measurement and inside measurement is very important for proper grating steel measurement. The inside measurement measures the gap distance between the vertical legs of angles and does not include thicknesses of both legs. The outside measurement measures the thicknesses of both legs and the gap distance between them.

Outside measurement is more precise

The outside measurement is more precise since the tape measure is nicely hook up on one side of the edge and is stretched under the tension passing the opposite side’s edge. Therefore in order to receive the length of the gap between the legs of an steel angle support we must measure outside dimension between the legs and then deduct the thicknesses of both legs.

The inside measurement measures directly the inside gap between the elements. The accuracy of inside measurement relies on strength of magnets in the hook when stretching the tape. Most importantly, we have to push the tape towards the hook to eliminate loose hook to get more precise measurement. And, that is why the inside measurement is less reliable. Each inside measurement should be confirmed with outside measurement for accuracy and vice-versa. Many people make simple math mistakes when calculating the inside gap.

Please remember accurate measurements guarantee that your grating steel panels will fit to their supports perfectly.

Outside and inside measurement example with suitable gap calculation

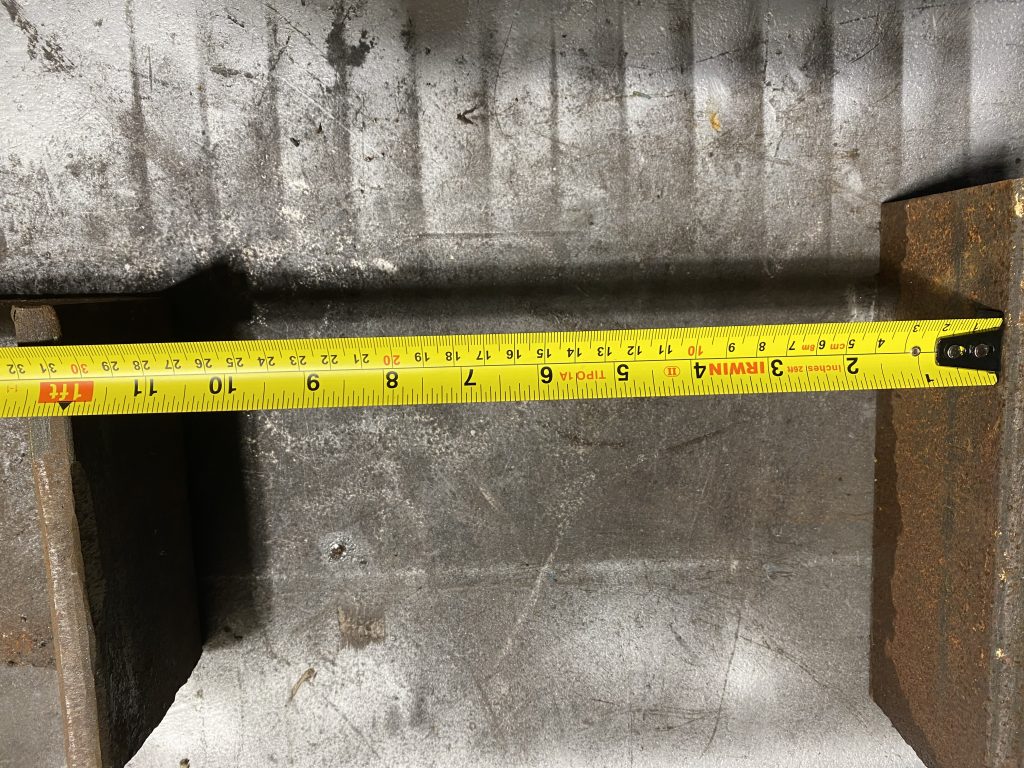

Here is inside measurement between legs of heavy angles.

The inside precise measurements are 12 1/8″ or 30.8cm

Now lets do the outside measurements for our comparison.

The outside precise measurements are 13 3/16″ or 30.5cm

Now we must measure thickness of the angles to deduct their thicknesses from the outside measurement to receive the distance of the gap between them.

The thickness of the angle is 12 mm or 1/2 inch.

Therefore calculations for the gap between angles’ legs for outside measurement are as follows:

- 33.5 cm – (2 x 12mm) = 335 mm – 24mm = 31.1cm

- 13 3/16″ – (2 x 1/2″) = 12 3/16″

Evaluation of differences and final decision.

The inside measurement of the gap is 12 1/8″ or 30.8cm but the gap with outside measurement is 12 3/16″ or 31.1 cm. Therefore the difference is 1/16 or 2mm between both types of measurements which is within tolerance of smallest gradient therefore out measurements are fairly accurate.

Which measurement should you provide to receive the quote?

Now you must make a choice between gap measurement of 12 1/8″ or 30.8cm and 12 3/16″ or 31.1cm. Which measurement is more correct? When both measurements are correct.

The correct question is. What measurement is more appropriate?

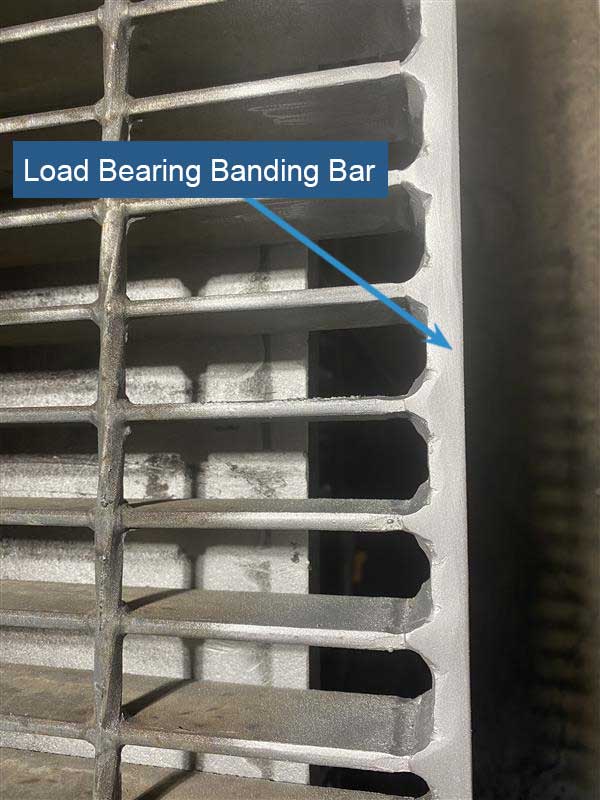

You should provide the smaller measurement since grating steel goes inside the gap. If you provide the smaller dimension and you were wrong the gap between the grating steel banding’s outside edge and the angle’s leg will be bigger. That is still Ok.

But, if you provide the larger measurement and you were wrong that the gap between the grating steel banding’s outside edge and the angle’s leg could be too small. Consequently, produced grating steel panels could not fit.

That is why you must always provide the smallest number to the grating steel producer. In the above example the measurement 12 1/8″ or 30.8cm is smaller and this is the right measurement to provide to grating steel producer.

Measurements of grating steel area

You have learnt in previous section how to measure with a good quality tape measure and how to find out the gap between the two opposite legs of an steel angle’s support. Now lets describe what to measure and what to watch for.

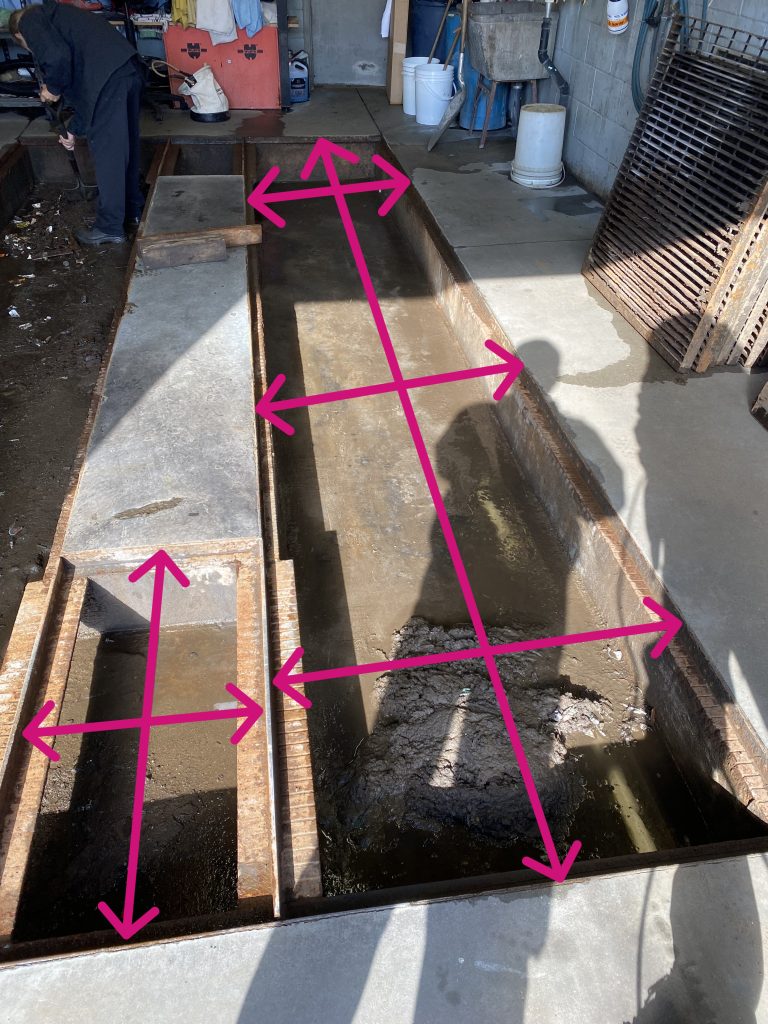

Please note that we measure width of the large trench at beginning, in the middle and at the end. In this way we will find out if the trench’s walls are bowing inside. We chose as the width the smallest measurement from all three.

We need to know the inside distances of length and width for each grating steel area. The image above shows 4 grating steel areas and two of grating areas have marked lengths and widths with red arrows.

Choosing the span direction of grating steel area

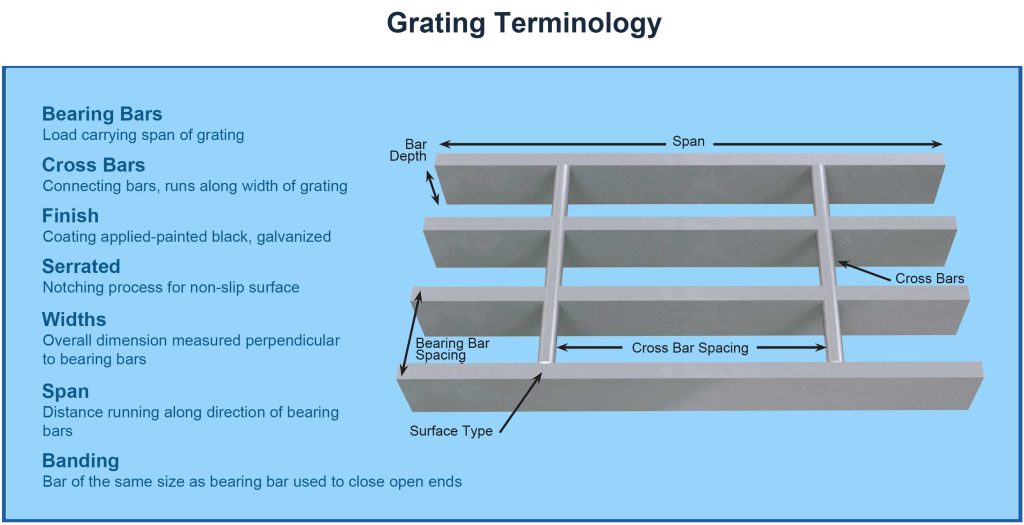

Now we must chose the span direction according to NAAMM guidance.

Please notice that span is the distance running along the direction of bearing bars.

Now, lets find out how the span of the panel runs within the trench.

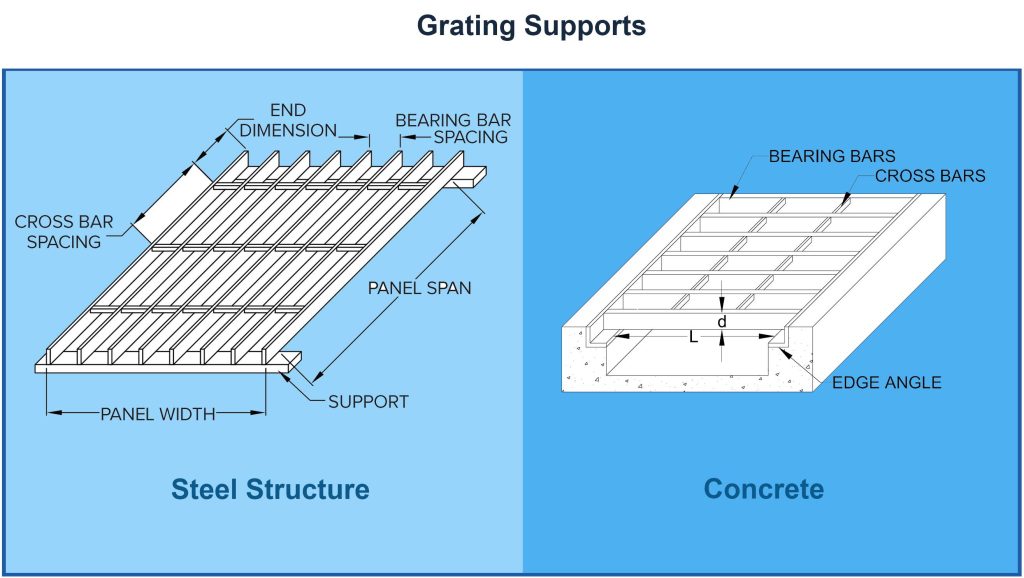

Span direction in concrete and steel structural support

Simply put, the golden rule of NAAMM for grating steel says. The span of the grating panel runs between the shortest supports. Therefore the span of grating steel panels runs along the width of the trench and the width of the panels runs along the length of the trench. In such position the grating steel bearing bars support the largest loads and resist highest impact.

Please notice on the image below the span direction of these 4 grating areas along with the traffic direction. The vehicular traffic direction should always be perpendicular to the span’s direction of grating steel panel. This is another golden rule of grating steel for vehicular traffic which is our area of specialization where we use our improvements to adapt the steel grating to dynamic loads. The second rule also means that the vehicular traffic should run perpendicular to bearing bars.

We need span direction for each grating steel panel prior quoting.

Please notice these two golden rules on the image below.

Consequences of span direction for grating steel

The span direction brings many consequences and some are more obvious than others. Here are some of more important consequences of establishing span direction:

- Instead of one panel going along the length of the trench, you will have many panels with their widths covering the length of the trench. The length of all these panels will go along the width of the trench.

- We have to cut long panels sold in 20 feet or 24 feet lengths into lengths that will fit into width of your trenches.

- We have to weld 2 banding bars to each panel to provide structural integrity to each panel. That means that we need to weld each bearing bar of every panel to responding banding bar on both sides of the panel. Since we provide antivibration welds we will place actually one weld per each side of bearing bar to the banding bar. Therefore the number of welds will double.

The antivibration welds allow to deal much better with dynamic loads of multidirectional vehicular traffic.

We need to know outside sizes for every grating steel panel

In order for us to produce panels we need to establish their sizes before production starts. We need to know each panel length along the span and its width. You can assume the maximum panel’s with to be 3 feet. But, smaller panels will have much smaller widths.

Most grating steel panels for vehicular traffic in secondary market are removed a few times a year for cleanup. These removable panels need at least 1/4″ or about 6 mm gap between the edge of the panel and the vertical leg of steel angle support. And, these panels need at least 1/4″ gap between the panels. However, some clients chose the bearing bars spacing as the distance between the panels in the trench. In our opinion, the distance between grating panels could reach the maximum limit of bearing bars spacing under two conditions:

- your panel’s span is within 60% of allowable span for maximum tolerable load of your panel’s type in your vehicular traffic conditions.

- your panels will not move under your vehicular traffic

Keeping the above information in mind, you will receive the length of the panels by deducting 1/2″ (1.3 cm) from the width distance of the trench. Then you will start adding width of panels along the length of the trench. The last panel will probably have smaller width. Additionally, you will have to reduce the width of the last panel by total widths of desired spacing between panels.

We need to know length and width of every grating steel panel prior quoting

Grating steel bearing bar depth or simply panel’s thickness.

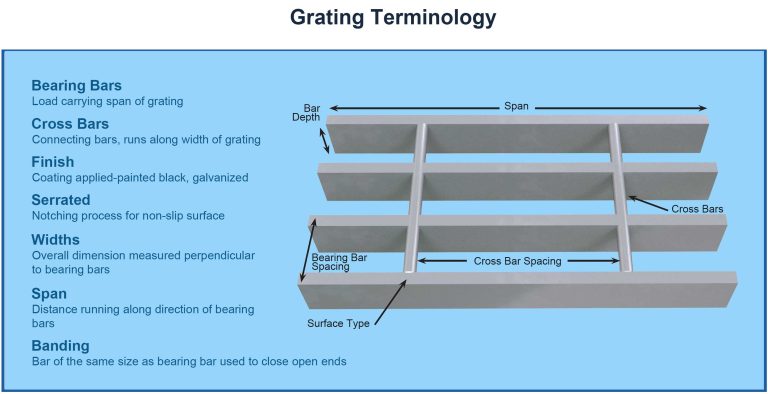

We need to know your steel grating bearing bar depth therefore please take a look at the grating steel terminology sketch to identify what it is a bearing bar depth. You can receive the bearing bar depth of your new grating by measuring old grating bearing bar depth.

This is the most practical way to receive bearing bar depth on ramps, pits and trenches.

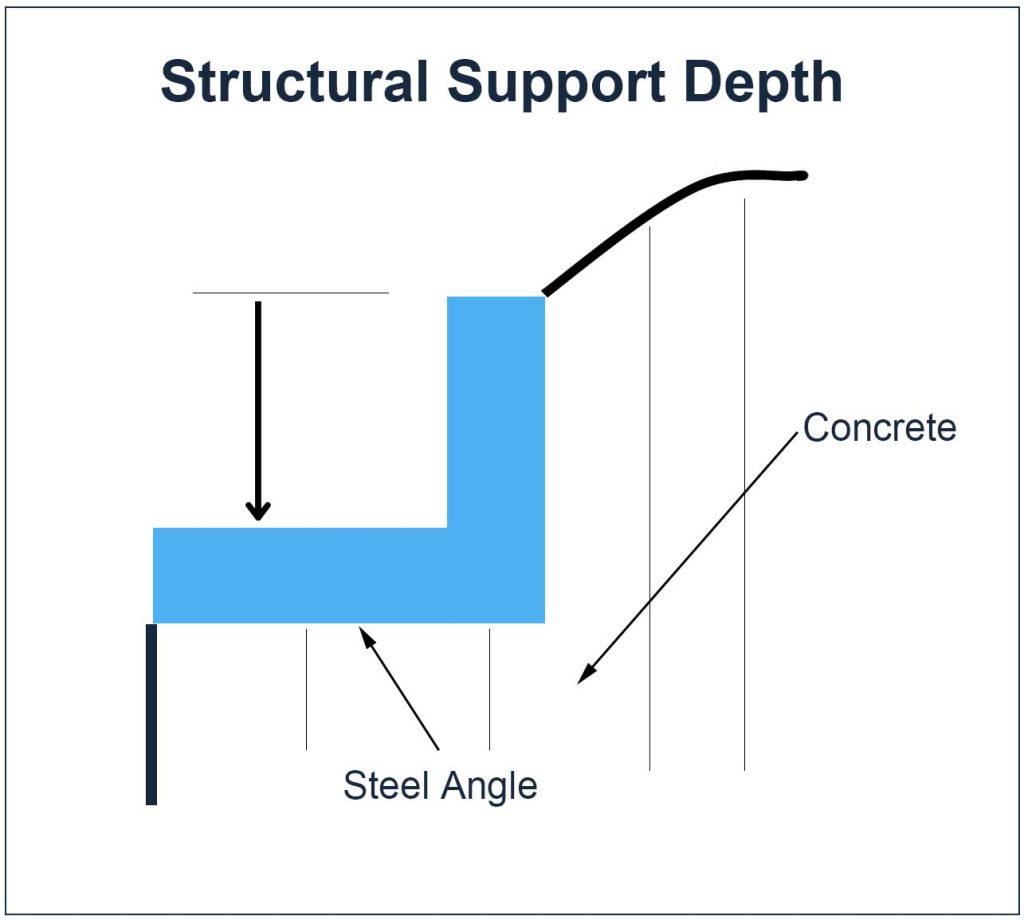

You can also measure the structural support depth as per sketch below.

Select location

We need to know where you plan to install your new grating steel panels. Since we produce customized grating steel the location is very important to us. It indicates to us the traffic direction characteristic, additional impact risk and possibility of drivers’ abuse.

The direction of traffic is paramount since there are significant differences of dynamic loads acting on multiple elements of steel grating. We recognize single direction of traffic, bidirectional traffic and multidirectional traffic.

The additional risk of impact is very important. Change of steel grating panel position from horizontal to incline or decline increases risk of additional impact. This additional impact takes toll on panels located at the bottom of the ramps on the incline and decline side. Additionally, panels located on the horizontal plane right after incline and panels located on the decline right after horizontal plane are at risk of additional impact.

Possibility of drivers’ abuse is a huge factor. The risk declines in locations such as mechanical shop and increases in warehouses and in factories.

Here are your choices of location for your steel grating

You must select your location from following choices:

- Warehouse

- Mechanical shop

- Factory

- Detailing shop

- Carwash

- Ramp

- Other

When you select “Other” please tell us more about your location

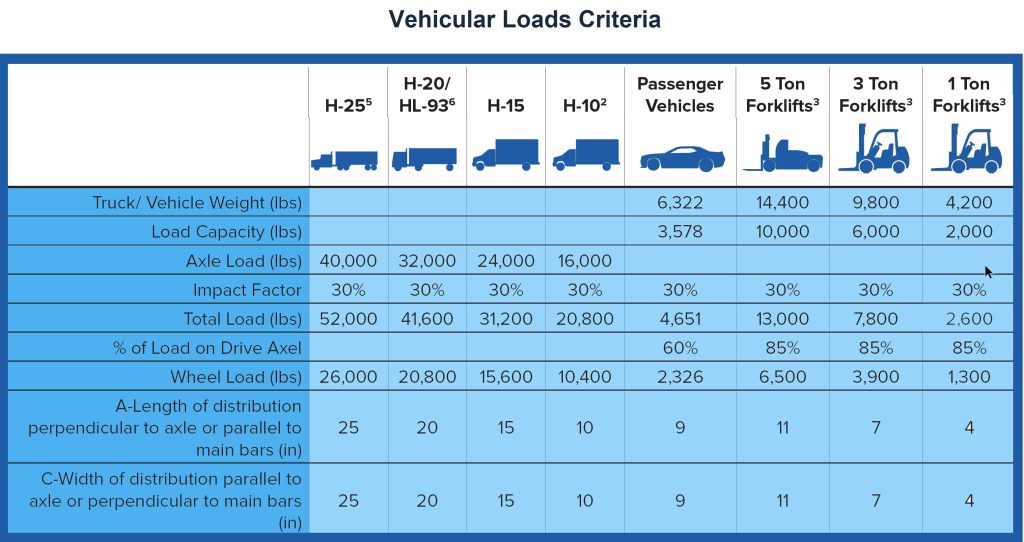

Select what will drive on new steel grating

You must tell us what vehicles will drive on the new grating. You should always assume the worst case scenario but please do not exaggerate. Exaggeration will increase the cost of grating in our estimate.

You must select from:

- Pedestrian traffic only

- 1 Ton Forklifts

- 2 Ton Forklifts

- 5 Ton Forklifts

- Heavier than 5 Ton Forklifts

- Passenger vehicles

- Pickup Trucks

- H-10

- H-15

- H-20 / HL – 92

- H-25

Please take a look at the image below for guidance in your selection.

Vehicle loading codes explanation

H – 10 A two-axle truck. The design criteria for H-10 involves axle loading of 16,000 lbs, or 8,000 lbs per wheel load.

H – 15. A two-axle single unit truck weighing 30,000 pounds (15 tons) with 6,000 pounds on its steering axle and 24,000 pounds on its drive axle.

H – 20 / HL – 93. A two-axle truck and HS-20 refers to a truck with more than 2 axles. The design criteria for both H-20 and HS-20 consists of truck axle loading of 32,000 lbs, or 16,000 lbs per wheel load.

H – 25. A two-axle truck and HS – 25 refers to a truck with more than 2 axles. The design criteria for both H – 25 and HS – 25 consists of truck axle loading 40,000 lbs or 20,000 lbs per wheel load.

Summary of our requirements for grating steel quote

We need to know following information

- Location of your steel grating

- Type of vehicles entering the grating area

- Exitance or lack of angle support

- Bearing bar depth in inches or centimeters for each grating area

- Inside distances of length and width for each gating area in inches or cm

- Length and width in inches or cm of each panel along with its span for each grating area quoted

- Serrated or Non Serrated and Unpainted or Galvanized. We recommend hot galvanization.

- Indicate need for custom improvements. I your grating steel panels last maximum 3-4 years than we recommend improvements

- Old grating steel’s bearing bar thickness and depth

- Images of your old steel grating areas and their panels. We need images of all most damaged grating panels taken from front and back.

- Sketches of grating panels arrangement within each area for more complicated area’s shapes only.

We also will need variety of images as specified on contact us page. Please remember to send us all images of your old steel grating installed in the trench, pit, drain or ramp. Then remove the worst damaged panel(s) and send us pictures of both sides for each most damage panel. These images will help us to evaluate your situation better. We will contact you if we have questions or when we find some inaccuracies in your measurements.