As our logo and banner suggest, we produce custom grated steel panels utilized in secondary market for vehicular traffic . We also produce some of more sophisticated panels of grated steel for pedestrian traffic. In essence we are expert in all applications where extreme impact, vibration and significant loads damage existing grating. We welcome all clients whose grated steel panels are being damaged by dynamic loads and excessive impact of multidirectional vehicular traffic.

JW Investrade Inc. is a mother company of JW Portable Welding & Repairs. On our specialization page we introduce you to metal grating world and create distinction of metal grating handled by metalgrating.ca from metal grating handled by JW Portable Welding & Repairs,

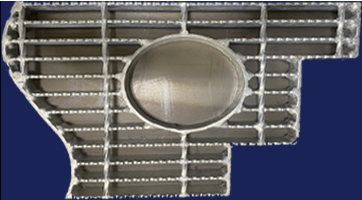

Our improved customization of grated steel panels involves improvements of existing panels manufactured by others, grating weldments for extreme situations and repairs of relatively old panels. We also produce compound grated steel in form of heavy duty drain covers for floors. Our drain cover also sustains extreme loads and impact.

Additionally, we also produce steel angle support for grate steel, including stainless steel angle support for stainless grated steel. In our service area, we implement improvements and repairs of grated steel support in variety of application.

We ship our highly customized grated steel panels Canada wide and we are ready to ship it to US.

Our grated steel expertise has grown over the years

We are a dominant mobile welding company for commercial projects in London, Ontario. Since beginning of our existence we have received calls to repair grated steel in ramps, trenches, and pits. Also we have repaired staircases, mezzanines and catwalks. The difference in nature of these repairs has been noticeable right away. The repairs on ramps, trenches and pits have focused on cracks of grating steel and twisted bearing bars. However, repairs of mezzanines and catwalks were rather related to steel structure supporting grated steel deck. The only exception of the rule were staircases with rusted steps, rusted steel grated decks and rusted steel structure. At that time, many years ago, we haven’t ask ourselves many questions regarding the nature of these repairs.

Repairs of grated steel

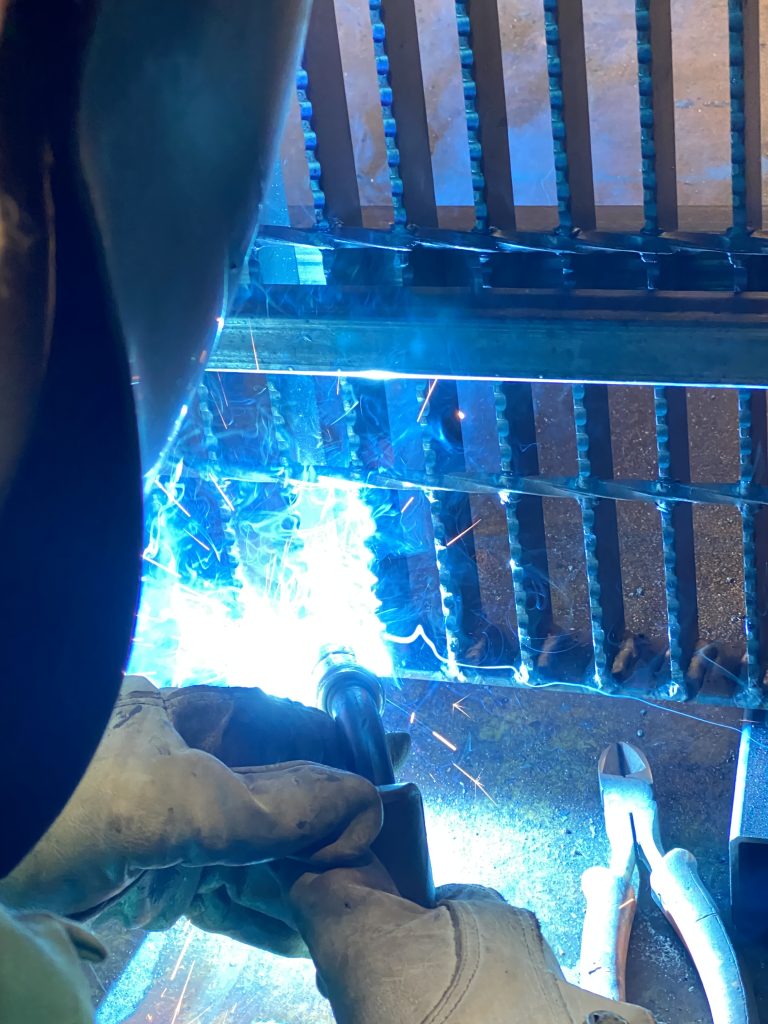

The mobile welding repairs of grated metal on ramps and trenches are very boring and tiring. They also bring minimal satisfaction to the welder performing these repairs. The welder spends hours on the knees performing hundreds of small welds in embryo position. Standing up becomes difficult due to lack of proper blood flow to the legs. Most importantly, this very routine job seems to never end since you see cracked metal all around you. When a welder looks back at the just finished section, he/she still notices missed cracks. This is very discouraging for any welder who is proud of his/her work.

Once you start replacing cross bars then more fun begins. You have develop a slightly different technique to weld them though. The next step was of course, use of different welding rod that offers higher tensile welds. Once the welder progresses with repairs of cross rods and their replacement process, then repairs of twisted bearing bars starts. This is when real fun starts in repair of grated steel. Next, you deal with broken bearing bars and missing banding bars and welding them in vertical position. Once everything has been fixed, you finish the project with the sense of accomplishment.

Next call from the same client can surprise the welder

When your client calls you back in a next year, you wander what you have missed. How should I do this differently? Then you visit the same spot and you cannot believe your own eyes what has happened there. And, the next step is obvious for any welder, you start making sketches. If you have engineering background than things will become more clear. Also, good common sense understanding of mechanical structures and its components helps a lot too. But, if you do not have these qualities than these sketches will end up at the bottom of the drawer.

Repair services

We repair damages of grated steel on ramps, pits, and trenches with radius of 150 km from London, Ontario. Same applies to repair of structural elements of mezzanines, catwalks and staircases. You can find more about our repair services of grated steel and its support structures here.

Structural improvement process of steel grates for vehicular traffic

The improvements of steel grate structures was the next step. We consider good quality grated steel an investment into operation of your business that suppose to last 25 – 30 years. Unfortunately, the reality is completely different. The dynamic loads of multidirectional vehicular traffic damages your grated steel panels within 10, 5, 2 years or even within 6 months. That is why we want you to invest in better quality grated steel that will not impact negatively operation of your business so often.

The multiple factors have contributed to our improvements of grating steel for vehicular traffic such as:

- in depth analysis of NAAMM recommendations with special attention to welding procedures as it refers to static loads

- analysis of banding bar’s damages

- analysis of longitudinal and traverse bows in reference to structural cracks

- analysis of leaned and then twisted bearing bars

Certainly, these analysis have not happened at the same time at once. Additionally, not all of them brought some tangible improvements to all types of steel grates. In fact, some analysis have only explained collaborating factors to sustained damages. Consequently, we are still aware of existence of other factors that need to be analyzed. The development of our improvements have rather had empirical nature since the analysis have only helped to understand the problem. Unfortunatelly, they have not provided solution right away. Therefore, we knew what the problem is and how it progresses but the correcting of this problem was not as easy due to:

- lack of welding space within the structure of grated steel

- the need for very precise cuts in specific location of the panel

- lack of proper welding procedures

- steel quality in some grates

- variety of structural components among different types of grates

- high cost, and

- impracticality of perfect solution

Our improvements

We improve steel grates for vehicular traffic that are produced by other manufacturers. Basicaly, we improve their resistance from static load to resistance of concentrated dynamic load. It means that we buy for our clients type of steel grates of known to us quality. This preferred by us quality includes quality of manufacturing and quality of steel itself. Certainly, it does not mean that other manufactures of grated steel have poor quality or their steel grates are not strong enough. It simply means that these manufacturers’ products suit our improvements and enhance their benefits.

Then we customize the improvements to fit our client’s needs in respect to dimensions of panels and their specific and concentrated dynamic load. This includes not only proper dimensions of panels with correct span direction but, most importantly, multiple improvements to specific panels. These improved panels will be placed in certain location in your grating area. Therefore our customization process involving your steel grate panels is not necessarily unilateral. In fact, some panels in specific locations are improved differently than others. Moreover, improvements of some panels in specific locations may apply to only some structural elements, but not to all of them. The plan of improvements is provided to our clients prior implementation and requires their approval.

Our skillful tradesmen are our assets

Due to high customization process of our improvements, all tasks directly involved into improvements are performed manually.

Therefore our certified welders perform all welding processes also manually. We have modified our welding equipment to perform the welding process on grate steel better.

List of our improvements of grated steel

Here is the list of our improvements

- thick banding bar,

- anti-vibration welds,

- size and length of welds,

- strengthening specific bearing bars within the structure of the panel

- strengthening edge or rim bearing bars

- cross bars at bottom of panel, and

- stabilization of bearing bars with spacers on ramp’s slopes or in sections with high amplitude and low frequency vibrations

Please visit our improvement page to find more about our customized improvements and how to contact us to improve your grated steel panels.

Grating weldments

The grating weldments was the next logical step in our technological development process. Unfortunately, some of our improved panels in locations exposed to high impact under heavy dynamic loads were still developing cracks. Definitely the panels restrictive depth was a main contributor to these cracks since it limits the thickness of these panels. Simply put, the old infrastructure cannot accommodate the thicker panels with grated steel depth. The thicker panels would provide greater resistance to high dynamic load and high impact in specific locations.

As many of panels of grating area do not exhibit any extra ordinary damages, some panels in the area sustain damages rather quickly. The heavy vehicle accelerating, or stopping, or changing travel direction, increases the dynamic load. This increased dynamic load that impacts destructively the grated panels. The damaging maneuvers include change in the direction of movement, decrease or increase the vehicle velocity, and taking additional load while standing on grated panels.

As an example we can use a forklift picking up a significant load while standing on the ramp’s steel grates. Than the forklift back off going backward down the ramp. The heavy forklifts with heavy loads damage grated steel most often when they change driving direction. Similar situation happens with semi trucks stopping on the ramp and going off the ramp to the asphalt level.

Location for our grating weldment

The grate steel panels directly under the wheels receive the excessive dynamic load and excessive impact. They are prone to damages precisely in spots touching the wheels. Since our improvements do not change the structure of grated steel panel, our improved panels also sustain these damages even though they last much, much longer. The only option left is to change the structure of steel grate panel and this is exactly what we have done to our grating weldments. As our grating weldments could be consider compound gratings their customization allows for improvements not possible in standard grating panels.

You can find more about our grating weldments and how to contact us to receive the quote for them.

Heavy duty floor drain covers

The customized heavy duty floor drain covers respond to our our client needs facing degradation of drain covers due to rust and excessive loads. Many of old drains have rarely standard sizes in our rapidly aging infrastructure. We custom produce drain covers that will fit the size of your existing drains. Also, since many of these old drains have completely rusted support structure for their drain covers, we produce drop in versions that do not need support structure.

Our heavy duty floor drain covers are in fact also compound gratings and they should be treated as such considering the dynamic load and impact they carry. These extremely ridged structures sustain also multidirectional vehicular traffic and turning of wheels while when they stand on them. This benefits these narrow trenches that sustain multidirectional traffic in many mechanical shops and car dealerships. This also benefits warehouses when forklift turns back wheels for small adjustment of forks direction while standing on a drain cover.

Many shops, warehouses and factories are overcrowded and change layout many times to make use of space more efficiently. Sometimes, it happens that the old drain does not allow to put the leg of heavy shelf, warehouse rack or work table on the drain’s cover. Our drain covers will sustain this static load and will provide the support to these loads.

You can find more information about our customized heavy duty floor cover and how to contact us to receive the quote.

Shipment and our service area

We ship our highly customized production of improved panels, grating weldments, and floor drain covers Canada wide and we are ready to ship to US. Whereas repair service of existing panels covers the area of 150 km radius from London, Ontario, where we are located. Therefore the purpose of this website is to provide educational support over the internet to clients in distant location starting from basic measurements, through explanation of fundamental concept of grated steel, and ends with available choices presented to you with our quote. We favor the practical simplified approach and step by step decision making in any problem resolution involving grated steel.

Metalgrating.ca mission and communication style

Our mission is to improve utilization time of grated steel panels and compound gratings that sustain extreme dynamic loads of multidirectional vehicular traffic in secondary market. Simply put, we attempt to increase your return of investment in operation of your business through reduction of frequent grated steel failures and reduction of frequent grated steel panel replacement.

We are the custom producer of grated steel panels in secondary market. The secondary market consists of businesses operating in facilities older than 10 years who are our clients, variety of grating steel importers, steel distributors and grated steel manufacturers. Grated steel product complexities can sometimes overwhelm clients with or without technical background. Therefore this website’s purpose is to simplify and educate clients about their choices prior purchasing any grating steel. Our direct communication also simplifies concepts as we explain grated steel challenges.

Communication style

Our simplifications throughout this website rely on simple images, drawings, suggestions and comparisons to draw important distinctions and conclusions. We even start with instructions how to measure grating steel and then plan the layout of grating steel panels within your grating area. We teach you everything you need to know to contact any manufacturer, producer or us to provide you with quote. You do not have to hire an engineer to help you with ordering even if you have never hold a tape measure.

Since beginning, we divide the novice buyers into two groups. These clients who seek grated panels for vehicular traffic and those who seek grated panels for pedestrian traffic. Each group learns what they need to know about grated steel separately since there are some significant differences between these panels. We also ask each group to have “Bar grating basic concepts” open for quick concept reference. Having this page open while reading many pages on our website will clarify the concepts of grate steel even faster. Our contact page implements step by step decision process into the field of grated steel in order to receive the quote from us. Our contact page suits novice as well as engineer specialized in the field of metal grating as they take different paths.

Complexities of grated steel for vehicular traffic in secondary market

The complexities of grated steel for vehicular traffic in secondary market involve

- sophistication of grated steel structure,

- manufacturer’s promotional message,

- ever increasing loads by heavier vehicles,

- aging infrastructure with related dimension restrictions, and

- clients without technical knowledge operating in fast pace environment

Having this factors in mind, we have decided that educating of clients should take the priority for us. Our clients face the most challenges in grated steel decision making. They also face the consequences of wrong purchases. On vehicular traffic page you will find introduction to grated steel terminology in simplified version in case you are dealing with replacement of grated steel for vehicles in your facilities. Over there you will also find description of types of grated steel used for vehicular traffic in secondary market and some of suggestions regarding our preferences. Since drains are important part of your water management in your facilities and they are heavily affected by vehicle traffic, we have included heavy build customized floor drain cover page too.

Sophistication of grated steel structures

Sophistication of grated steel structure impacts the way:

- how we learn about it,

- how it is manufactured

- how it is distributed, and

- how it is sold to you

There are basically two ways to go about it, the long and frustrated way and the metalgrating.ca way.

Long and frustrated way is not for everybody

Sophistication of grated steel structure could become overwhelming for novice who deals with basic replacement of grated steel. The novice client should become more familiar with basic terminology to understand the concepts, then must comprehend tens of drawings to develop knowledge regarding basic manufacturing standards in order to draw conclusions which type of grated steel is useful in his/her facilities.

Then you call your steel supplier and they tell you that they handle only one type of grated steel that is sold in panels of 24 feet long. This 24 feet long panel perhaps will be very useful for large steel fabricators to fabricate a mezzanine, or a catwalk but it will not fit to your trenches. Slightly frustrated, you call next the reputable manufacturer who asks number of strange questions. You call them again a week later once you do your homework and provide them with measurements, then they will quote it but you have to wait for the delivery 6 months. They can also tell you that your project is too small for them or they simply will not respond.

The metalgrating.ca simplified way

In about 1 hour you will learn what you need to know to replace the old grated steel for vehicular traffic including terminology, specific measurements we need to know and how to take them. Then you go to contact us page that will guide you what additional details we need to know to supply the grated panels for your facility. Additionally, we also ask for basic and simple information regarding maximum load, and we also ask for images of your old grated steel to judge the actual load and impact.

Then we verify your information based on supplied questionnaire and we eliminate any possible mistake you could have done. Finally, we quote your project based on type of grating you need and based on additional improvements your projects require to extend your utilization time as long as possible. We will give you a few choices.

If you decide to place the order with us, you will also benefit from our standard and/or more advanced improvements to your grated steel panels. Our turnover is about 1.5 months therefore you can expect shipment to any location in Canada or US within 7 weeks. The grated steel panels will fit perfectly into your facilities and the installation of them will go smoothly since we will include out lifters free of charge. And, most importantly these panels will last much longer due to improved maximum dynamic load and impact resistance.

Vehicles are getting bigger and heavier

The vehicular traffic is changing in front of our eyes, our cars, pickup trucks, heavy trucks, semi trucks are getting bigger and heavier. The electrical vehicles entering market are about 30% heavier than their predecessors, not to mention hybrids that contain battery and the gasoline engine. Our heavy machinery including agricultural equipment, excavation equipment, forklifts, and other construction equipment is getting bigger and heavier too.

Old facilities face dimensional restrictions

Unfortunately, facilities of secondary market clients are getting older and older and hardly can handle all this increased load and impact. The frequency of increased traffic is getting also bigger with growing efficiencies at every corner. That is why the excessive load and impact in heavy traffic going in multiple directions is crushing grated steel panels.

Manufacturer promotion is diluted in distribution and low price rules the game

The American and Canadian manufacturers under guidance of ANSI and NAAMM produce technologically advanced grated steel. Their innovation message is getting diluted with products going from major distributors to local distributors and then from local steel distributors to their customers. Additionally, importers push foreign grated steel to distributors at very attractive prices without any surrounding explanation regarding load and impact. Or, in fact, any consideration for quality of steel for this grated product. And, as we all know, low price speaks volumes.

Clients lack basic grated steel knowledge

Clients without preventative maintenance programs, and without any structural engineering background face crucial decisions regarding complex grated steel product in fast pace environment. The vicious cycle of improving the damaged grated steel with the same type of grating and expecting different results dominates. As long as it fits is the main concern for many who sometimes do not know how to read a tape measure.

Our customers include factories, dealerships, mechanical shops, warehouses, water treatment plants, chemical plants, mining, pulp & paper, oil refineries and petrochemical plants, railroads, airports, agricultural facilities and many other commercial businesses.

Pedestrian secondary market is dragging its feet

The grating steel secondary market for pedestrians is dragging its feet in comparison to vehicular market. In this market mezzanines and catwalks with long grating steel panels rule the market. In this market proper engineering planning takes time, and suppliers of grated steel have months for scheduled delivery. Unfortunately, we do not supply long grating steel panels for mezzanines and catwalks. Additionally, we do not supply stair steps made from any grating material. We simply focus on what we do best and leave this market to large fabricators that use relatively long panels in unimproved form.

However, we are present in some niche pedestrian markets. We also repair supporting structures for grated steel within our service area, that involves also replacement of rusted bottom of the column that supports the load of mezzanines and steel staircases. We can do these replacements without use of any crane.

Production of grated steel panels for pedestrian traffic with unusual shape

We produce grate steel panels with very attractive shape to fit the needs of our industrial clients as well as shopping centers and dense urban centers. As these unusual shape panels fit your complex designs, they also allow structural engineers to build mezzanines with close access to stationary machines that do require frequent inspections and maintenance.

Production of grate steel panels for large pits without traditional angle steel support

In many old condominium and apartment building complexes these pits provide ventilation access to underground warehouses. They are located in proximity to underground parking and they are accessible by the public whether intentionally or by mistake. Therefore they must have draining cover for pedestrian traffic. These old pits sometimes have cover from expanded metal grate but it is often severely damaged by rust. More importantly, these old covers do not meet the new building codes.

These old pits most often do not have any steel angle support for their drain covers therefore we produce the drop in sectional versions with reverse heavy angles as the rim. The two men crew can install such drop in sectional drain cover in minutes without any help of crane.